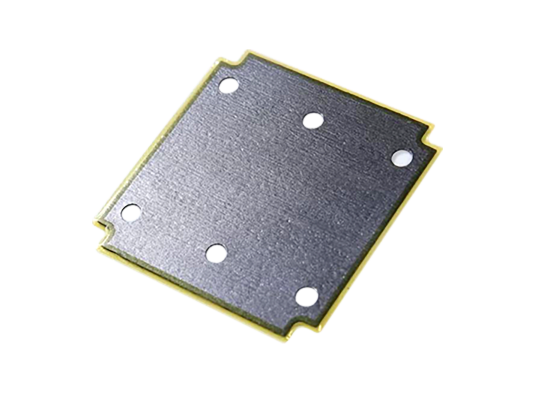

Graphene high thermal conductivity gasket is a new type of ultra-thin thermal gasket with ultra-low thermal resistance. This thermal pad mainly uses two-dimensional materials as thermal fillers, and utilizes advanced preparation techniques to arrange the two-dimensional materials in an orderly manner in a polymer matrix, forming a good thermal conductivity path and greatly improving the thermal conductivity efficiency. It is particularly suitable for high heat flux density equipment such as base stations and chips. In addition, the super Pu thermal conductive gasket has the characteristics of high resilience, low density, and is not easily deformed, and can be used as a substitute material for thermal conductive silicone grease.

Product performance

| NO. | Parameter | Test method | |||

|---|---|---|---|---|---|

| Color | Black | Visual inspection | |||

| Maximum standard size(MM) | 90*90 | ASTM D5947 | |||

| Thickness(MM) | 0.2~0.5(±10%) | ASTM D 374 | |||

| Density(G/CC) | s0.6 | ASTM D 792 | |||

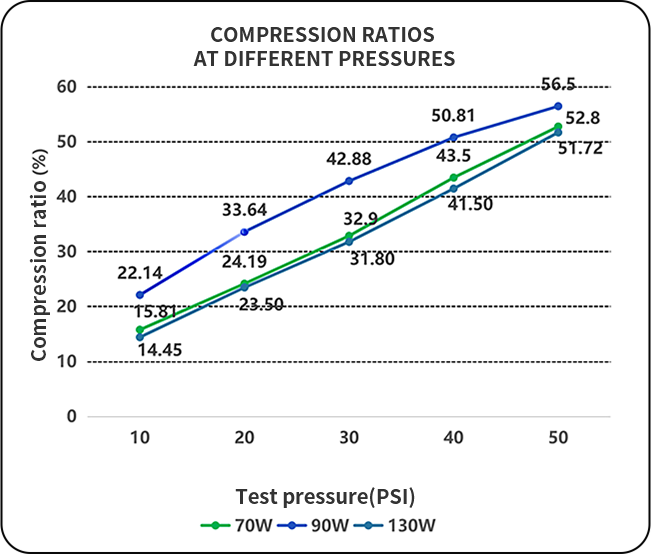

| Compressive stress(PSI) | ≤65(@50%) | ASTM D575 | |||

| Tensile strength(Mpa) | Orientation | ≥0.05 | ASTM D412 | ||

| Vertical | ≥0.025 | ASTM D575 | |||

| Resilience(%) | 260 | ASTM D575 | |||

| Creep behavior(MM) | ≤1 | ASTM D 575 | |||

| Oil leakage rate(%) | ≤3 | CSMH | |||

| Operating temperature(℃) | -40~125 | IEC 60068-2-14 | |||

| Thermal properties | |||

|---|---|---|---|

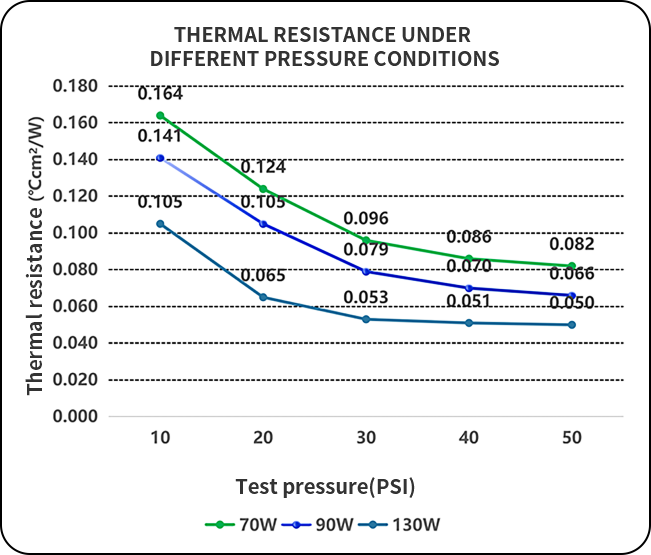

| Thermal resistance(℃ ·cm²/W) | @20psi | ≤0.11 | ASTM D5470 |

| @40psi | ≤0.09 | ASTM D5470 | |

Application features

01

Soft surface and

good compressibility

02

Low density

03

Low thermal resistance

04

High resilience

05

Good thermal

stability

performance

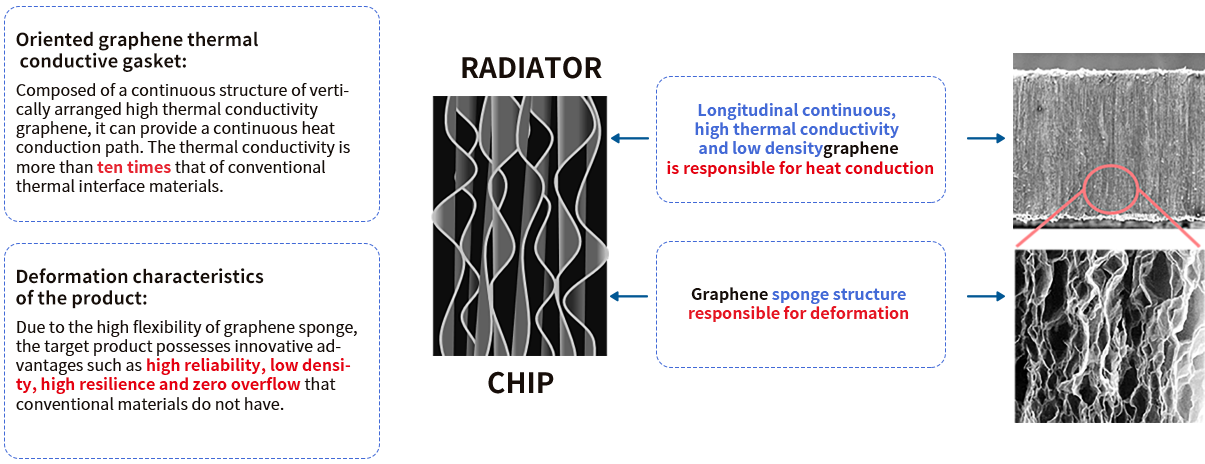

Innovative thermal conductivity structure of graphene high thermal conductivity gasket

Thermal resistance test of graphene thermal conductive sheet

The thermal resistance gradually decreases with increasing pressure and then remains stable. It is recommended to use a pressure of ≥ 20psi

Application field

5G base station

AI chip

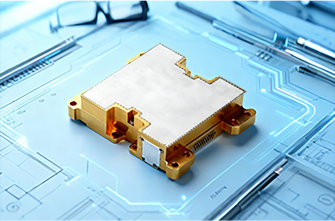

T/R component

Charging of new energy vehicles