Why sit firmly in the position of precision machining with diamond cutting tools?

Diamond is used in the manufacturing of ultra precision machining tools due to its extremely high hardness, wear resistance, high thermal conductivity, and low affinity with non-ferrous metals.

Why can diamond cutting tools occupy a key position in precision machining for a long time in the face of the rapidly developing manufacturing industry? The editor of Powder Network believes that sufficient hardness is a basic condition, and the key is that diamond can continuously refine itself. By refining and continuously improving the types and application scenarios of cutting tools, we are also adept at extending their service life and exploring technologies to enhance cutting performance in the microscopic world.

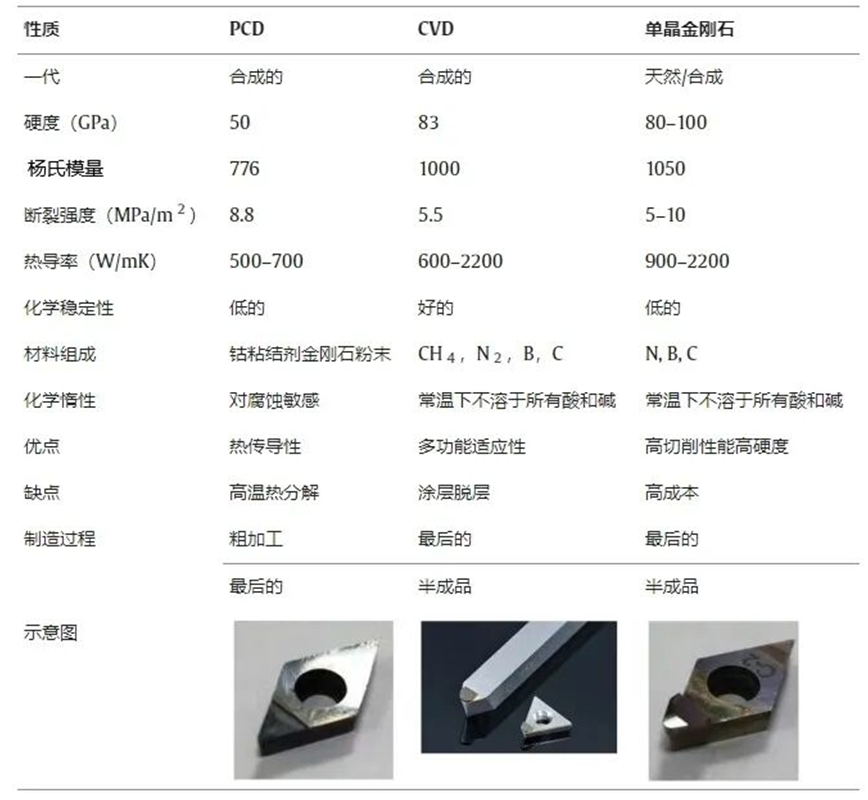

Performance comparison of different diamond tools

Single crystal diamond tools were previously widely used for processing non-ferrous metals such as aluminum, copper, and gold, with tool life reaching several thousand kilometers. In recent years, single crystal diamond cutting tools have been used to process non-ferrous metal materials, gradually shifting towards hard and brittle materials (such as optical glass, silicon, silicon carbide), and iron-based materials (such as iron, manganese, chromium, etc.). The rapid wear of cutting tools limits the application of ultra precision machining in the field of difficult to machine materials

High temperature and high pressure diamond (HTHP) performs better than natural diamond, with no impurities or inclusions inside, and controlled nitrogen content, providing consistency and uniformity for the tip. Compared with natural diamond, HTHP diamond has superior fracture strength, hardness, and thermal conductivity.

However, cracks, internal bubbles, and pits in HTHP diamond can affect the accuracy and surface roughness of the tool. In addition, the HTHP diamond synthesis method can synthesize large-sized single crystal diamonds, but the high cost and difficult control of this method make it difficult to promote.

Compared with HPHT diamond cutting tools, CVD diamond coated cutting tools have significant advantages. The main advantages of CVD include the ability to control the deposition rate of coatings and achieve uniform coatings on complex shapes. CVD diamond coated cutting tools also have the advantages of high hardness, good wear resistance, and strong chemical stability, playing an important role in processing difficult to machine materials such as aluminum, silicon alloys, metal matrix composites, and graphite.

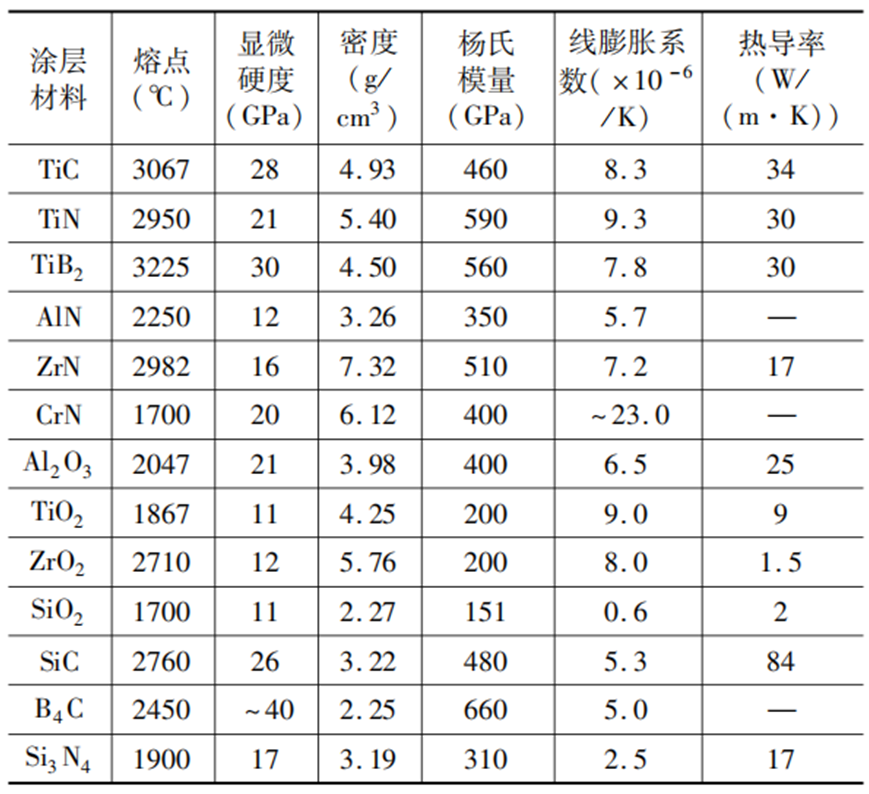

Coating materials act as chemical and thermal barriers, avoiding direct contact between tools and workpieces, reducing friction and interaction between tools and workpieces, enhancing the anti-oxidation, anti bonding, and anti-wear properties of tools, thereby extending their service life and improving their cutting performance.

For example, based on the excellent performance of boron doped diamond, the development of boron doped nanocrystalline diamond cutting tools (NPD) has become a pioneering approach in the research and development of diamond cutting tools. Boron doped NPD cutting tools exhibit excellent wear resistance when cutting non-conductive ceramics and metals. Optical glass materials highlight their enormous potential in processing hard and brittle materials.

For CVD diamond coated cutting tools, improving the adhesion of diamond coating is still a key obstacle that needs to be overcome. Research has shown that boron and cobalt can form stable phases at the interface, thereby improving the residual stress of diamond layers. This provides direction for improving the bonding strength between the diamond material layer and the substrate. It should be noted that the manufacturing process of boron doped diamond cutting tools is relatively complex, requiring strict control of boron doping concentration, coating uniformity, and adhesion.

Common Performance Parameters of Hard Coatings

In addition, solid lubricating materials with low friction coefficient (such as C, MoS2, WS2, CaF2, etc.) are coated on the tool surface through surface coating technology. During the cutting process, the solid lubricating film will transfer from the tool surface to the workpiece surface and form a transfer film, causing friction to occur between the transfer film and the lubricating film, effectively reducing friction, preventing adhesion, lowering cutting temperature and cutting force, and ultimately achieving the goal of reducing tool wear and preventing chip formation.

In order to better solve the problem of difficult to machine materials, researchers have adopted different feasible methods to enhance the performance of diamond cutting tools. Based on surface coating technology, surface texture technology and the combination technology of micro nano texture coating technology have been studied.

By using surface texturing technology to prepare different types of micro and nano textures on the tool surface, the frictional behavior of the tool chip contact surface and the tool workpiece contact surface can be improved, the anti adhesive wear performance of the tool can be enhanced, the cutting force, cutting temperature, and friction coefficient of the tool chip contact interface can be reduced, thereby enhancing the cutting ability of the tool and extending its service life.

Both types of tool surface modification techniques can improve the thermal and mechanical properties of the tool surface, thereby enhancing the cutting effect. Research by Tian Chuchun et al. has shown that incorporating micro/nano textures and coatings onto the cutting surface of cutting tools through surface texturing and surface coating techniques can significantly improve cutting performance; Especially in reducing tool wear, cutting force, cutting temperature, and friction coefficient at the tool chip contact interface, it has significant effects.

Single crystal diamond is a very expensive material, typically priced around four times higher than polycrystalline diamond cutting tools (PCD). Cheap PCD tools have excellent performance, such as ultra-high hardness (8000HV ≈ 78.4GPa), high wear resistance, and excellent thermal conductivity (560 • W/m • K). PCD is a composite material made by mixing selected micrometer sized diamond crystals with a small amount of metal powder (Co), and then sintering at high temperature (1400 ℃) and high pressure (6Gpa).

Due to the limited toughness of PCD, most industrial PCD tools use hard alloys as substrates. PCD tools contain Co and other metal binders, which enhance their fracture toughness. However, Co affects the hardness of PCD itself. In addition, Co accelerates the conversion of diamond to graphite at high temperatures. Therefore, PCD tools are highly suitable for semi precision machining and tool requirements with high fracture toughness.

Precision machining is still developing rapidly, and diamond cutting tools still need to be tempered themselves.