Active Phased Array Radar Integration: Overcoming Five Major Challenges to Achieve "Compact Size and High Performance" Breakthroughs

The integration of Active Phased Array Radar (APAR) essentially solves the bottleneck of traditional radar (such as mechanical scanning radar and early passive phased array radar) in core dimensions such as "performance, volume, reliability, and power consumption" through "high-density integration of multiple devices/functions, modular design, and collaborative optimization", ultimately meeting the stringent requirements of modern equipment (such as fighter jets, destroyers, early warning aircraft, satellites) for "high performance, miniaturization, high reliability, and low energy consumption" of radar.

Integration is not simply a matter of "component assembly", but rather a systematic solution to the bottlenecks of traditional radar in the five dimensions of "spatial adaptability, performance efficiency, reliability, multitasking capability, and cost" through "high-density hardware integration, software control, and modular design". The ultimate goal is to provide higher detection performance, more reliable working conditions, and more flexible multitasking capabilities with lower power consumption and cost in a smaller volume - this is also the key reason why active phased array radar can become the "core perception center" of modern equipment.

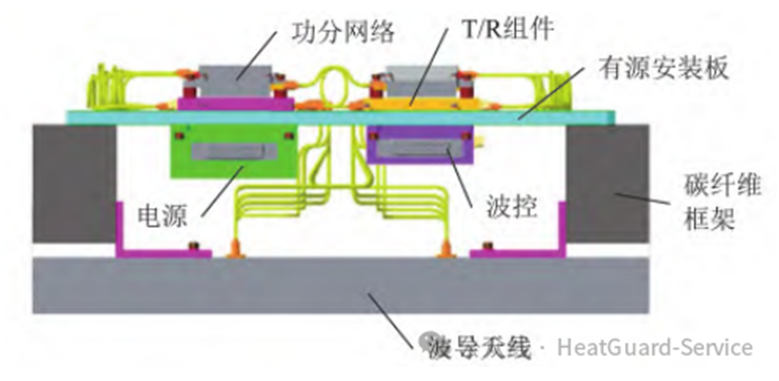

Figure 1 Sectional view of brick type active phased array antenna architecture

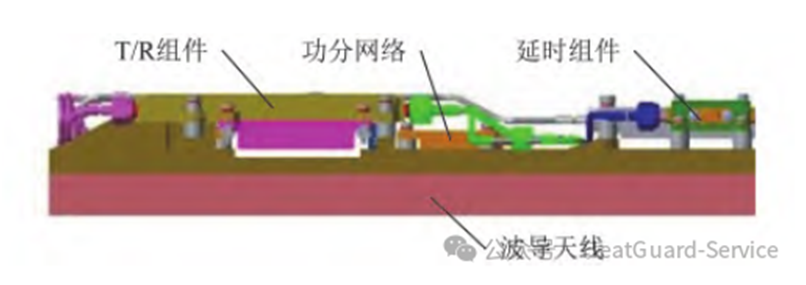

Figure 2 Cross sectional view of integrated active phased array antenna architecture

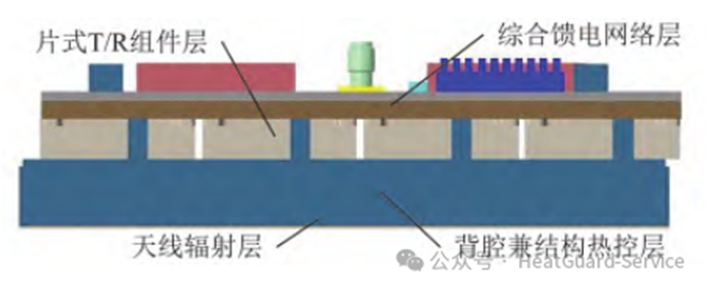

Figure 3 Cross sectional view of chip active phased array antenna architecture

Five key issues

1、Resolving the Contradiction between Performance and Volume: Breaking through Equipment Space Limitations

The space of modern equipment (such as fifth generation fighter jets, shipborne radars, and vehicle mounted radars) is extremely limited (for example, the space inside the radar cover of fighter jets is only a few cubic meters, and shipborne radars need to adapt to the size of the ship island), but the demand for radar performance (detection range, resolution, multi-target tracking ability) continues to increase - the "discrete architecture" of traditional radars (independent arrangement of functional modules, numerous cables/connectors) can lead to "large volume and excessive weight", which cannot adapt to equipment space; Integration, through high-density integration, can achieve high performance within a limited space.

TR component integration: Integrating traditional dispersed devices such as low-noise amplifiers (LNAs), power amplifiers (PAs), mixers, and digital attenuators into a miniaturized TR module (such as integrated TR components using GaN (gallium nitride) chips, which have a volume only 1/5~1/10 of traditional discrete solutions);

Multi module collaborative integration: Integrating core modules such as TR component array, beam control unit, signal processing unit, and power unit through "integrated packaging" or "common substrate design" to reduce cable connections between modules (cable losses account for 30%~50% of total losses in traditional discrete architectures), while significantly reducing overall volume and weight.

For example, the AN/APG-81 active phased array radar of the US F-35 fighter jet integrates about 1600 TR modules inside the radar cover through the high integration of TR components, with a total weight of only about 150kg. However, it achieves the performance of air detection range exceeding 160km and tracking more than 20 targets at the same time, while early mechanical scanning radars (such as the AN/APG-68 of the F-16) weigh over 200kg and have a detection range of only about 100km.

2、Addressing the issues of signal loss and energy efficiency: Enhancing radar detection capabilities

The core performance of active phased array radar (such as detection range) is directly related to "transmission loss of RF signals" and "power utilization efficiency" - in traditional discrete architectures, "signals from the transmitting end to the antenna" need to go through multiple independent modules, long-distance cables, and connectors, and each step will result in signal attenuation (i.e. "link loss"); At the same time, the dispersed power consumption and low heat dissipation efficiency of discrete devices lead to serious waste of "effective radiated power (ERP)", ultimately weakening the detection capability of the radar.

Reduce link loss: Integration will make the "signal generation, amplification, frequency conversion, radiation" and other links highly compact, shorten the distance between modules from "meter level" to "millimeter level", reduce the number of cables/connectors by more than 90%, and reduce link loss from traditional 15-20 dB to 5-8 dB (note: 10dB loss means only 1/10 of signal power is left, while 5dB loss retains more than 30%);

Improving power efficiency: adopting "chip level integration" (such as SoC, SiP technology), directly coupling the power amplifier (PA) of the TR component with the antenna unit (i.e. "antenna TR integrated design"), to avoid power waste during transmission; At the same time, integrated power modules can accurately supply power to different devices' power consumption requirements, reducing "ineffective power consumption" (such as the conversion efficiency of traditional discrete power supplies being about 70%, while integrated power modules can reach over 90%).

For example, shipborne active phased array radar (such as the 346A/B radar of China's 055 destroyer) integrates TR components directly with the antenna array through integrated design, significantly reducing link loss. Its detection range for airborne targets can reach over 400km, far exceeding traditional shipborne mechanical scanning radar (such as the US SPY-1 passive phased array radar, with a detection range of about 300km).

3、Solving the "Reliability and Maintenance Challenge": Reducing Failure Risk and Costs

The "discrete architecture" of traditional radar has two major reliability bottlenecks:

High risk of single point failure: Discrete modules rely on a large number of cables and connectors for connection, which are prone to loosening or damage due to vibration (such as aircraft flight, ship turbulence) and environmental corrosion (such as high salt spray on the sea). Once a connector fails, it may cause the entire radar chain to fail;

Difficulty in maintenance: Discrete modules are arranged in a scattered manner, and fault location needs to be checked one by one (such as checking the continuity of dozens of cables). Maintenance time is long and cost is high (according to US military data, the average time to repair (MTTR) for traditional radar is about 24 hours, while integrated radar can be shortened to 2-4 hours).

Integration solves these problems through "modular, high reliability design":

Modular redundancy design: Split the radar into multiple "independent integrated modules" (such as integrating TR component arrays into "subarrays", each subarray containing dozens of TR modules), and connect the modules through standardized interfaces - if a subarray fails, only that subarray needs to be replaced without affecting the operation of other modules (i.e. "redundant fault-tolerant");

Reduce vulnerable components: Integration significantly reduces the number of cables and connectors (for example, traditional radar has hundreds of connectors, while integrated radar only requires dozens), while adopting "sealed packaging" (such as metal shell+waterproof glue seal) to resist harsh environments such as vibration, salt spray, high temperature, etc., reducing the probability of failure;

Intelligent fault diagnosis: The integrated module is equipped with a "health monitoring chip" (such as temperature and current sensors), which can collect real-time device status data and quickly locate the faulty module through the backend system (if a TR module has abnormal current, the system can directly display its location), without the need for individual troubleshooting.

4、Solving the "Multi functional Collaboration Challenge": Achieving "One Radar Multi Task"

Modern combat scenarios require radar to have "multi task parallel capability" (for example, fighter jet radar needs to simultaneously complete "air detection, sea search, electronic countermeasures, and communication relay"; shipborne radar needs to simultaneously complete "remote warning, target tracking, and missile guidance"). The various functional modules of traditional discrete radar work independently, and signals cannot be efficiently shared, making it difficult to achieve multi task parallelism (such as switching between "air" and "sea" modes requiring readjustment of hardware links, which takes several seconds).

Hardware resource sharing: Integrating core hardware such as signal generation, frequency conversion, and processing into a "universal platform" (such as integrated intermediate frequency processing units and digital beamforming (DBF) units), allowing different tasks (such as detection and adversarial) to share the same hardware without the need to repeatedly configure independent modules;

Software based control: The "beam control and mode switching" of integrated radar are implemented through software (i.e. "software defined radar") - for example, by adjusting the phase and amplitude of TR components, multiple independent beams can be generated at the same time, which are used for "airborne detection" (wide beam, long-range) and "target tracking" (narrow beam, high-precision), and the beam switching time is shortened from the traditional "second level" to "microsecond level";

Multi band fusion: Some high-end integrated radars can achieve "multi band integration" (such as simultaneously integrating X-band (high-precision), S-band (long-range), and L-band (anti-interference)), fusing multi band data through integrated signal processing units, balancing detection range, accuracy, and anti-interference capabilities (such as the AN/MPQ-65 radar of the US Patriot air defense system, which achieves X/S dual band coordination through integration).

5、Resolving the contradiction between cost and batch application: promoting the popularization of radar

Early active phased array radars were extremely expensive due to their "discrete design, manual assembly, and high device costs" (such as around 2000, the cost of a shipborne active phased array radar exceeded $100 million), and could only be equipped with a few high-end equipment (such as the US Aegis class destroyer). Integration reduces costs through standardized and large-scale production, promoting its popularization towards mid to low end equipment.

Standardized design: The integrated module adopts a "universal interface, unified packaging" (such as TR components designed according to international standard sizes), which can be mass-produced, interchangeable and universal, reducing customization costs;

Automated manufacturing: Integration relies on automated processes such as surface mount technology (SMT) and multi chip module (MCM) packaging, replacing traditional manual soldering (such as manually soldering cables for discrete devices, and machine mounted dozens of chips for integrated modules), increasing production efficiency by 10-20 times and reducing labor costs by more than 50%;

Localization/scaling of devices: Integration promotes the large-scale application of core chips such as GaN (gallium nitride) and SiC (silicon carbide) (for example, the cost of GaN chips decreases with increasing production, with a unit price exceeding $1000 in 2010 and dropping to $100-200 in 2024), further reducing overall costs.

For example, China's domestically produced active phased array radar has been widely used in "non high-end" fighter jets such as J-10C and J-16, as well as equipment such as 052D destroyers and vehicle mounted air defense systems, through integrated and large-scale production, with costs reduced by more than 60% compared to earlier models.