Sinomach Precision has successfully developed diamond copper products, targeting the heat dissipation sector

Recently, China National Machinery Industry Corporation Limited released an investor relations activity record form. Guoji Precision Industry stated that diamond has excellent heat dissipation performance, but cost constraints limit its functional application. In the future, with the development of high-power devices and high-performance chips, heat dissipation issues will become increasingly prominent, and diamond as a heat dissipation material may gain a place. In the field of diamond heat dissipation applications, in addition to diamond heat sinks, the industry has also launched diamond copper composite material products. The heat dissipation performance of diamond copper composite materials is between that of copper and diamond, but its cost is lower than that of diamond, and it has good application prospects. The company keeps up with the pace of the industry and has successfully developed diamond copper products, which are currently being promoted in the market.

Image source: Official website of China National Machinery Industry Corporation

Excellent performance of diamond copper

Developing thermal management materials with excellent thermal performance to achieve efficient heat dissipation is a key issue in the development of the electronics industry. Diamond copper has become an ideal thermal management material due to its high thermal conductivity and suitable coefficient of thermal expansion.

Ultra high thermal conductivity: The theoretical thermal conductivity of diamond can reach 2200 W/(m · K), but its practical application is often limited by interface thermal resistance. By optimizing the interface bonding between diamond particles and copper matrix, the thermal conductivity of the composite material is significantly improved. According to relevant data, the use of diamond copper heat dissipation components can reduce the average operating temperature of 5G base stations by 25% and reduce power losses by 10%. In terms of computer CPU heat dissipation, the use of diamond copper made heat dissipation fins can more efficiently transfer the heat generated by the CPU, maintain the low-temperature operation state of the CPU, and effectively improve the performance and stability of the computer.

Low coefficient of expansion: The coefficient of thermal expansion (CTE) of diamond copper composite materials can be precisely controlled by adjusting the diamond content. As a packaging material or heat dissipation substrate for chips, its low coefficient of expansion can match the thermal expansion coefficient of semiconductor chips, reducing the generation of thermal stress and ensuring the stable operation of chips.

High hardness and wear resistance: In some extreme working conditions, materials need to have high hardness and wear resistance to ensure the normal operation and service life of equipment. Diamond copper has been widely used in aerospace, automotive manufacturing and other fields due to its high hardness and excellent wear resistance.

National Machinery Precision Industry has advantages in the field of diamond heat dissipation

Guoji Precision Industry shoulders the important responsibility of "strategic technological strength in forging machinery industry" in the industrial basic research and service sector of Guoji Group, and is in a leading position in China in areas such as bearings, superhard materials, and machine tools. Relying on the profound accumulation of "Three Grinding Institute" in the field of superhard materials, Guoji Precision has taken the lead in laying out diamond heat dissipation technology and achieved multidimensional breakthroughs in process research and development, equipment manufacturing, and other aspects.

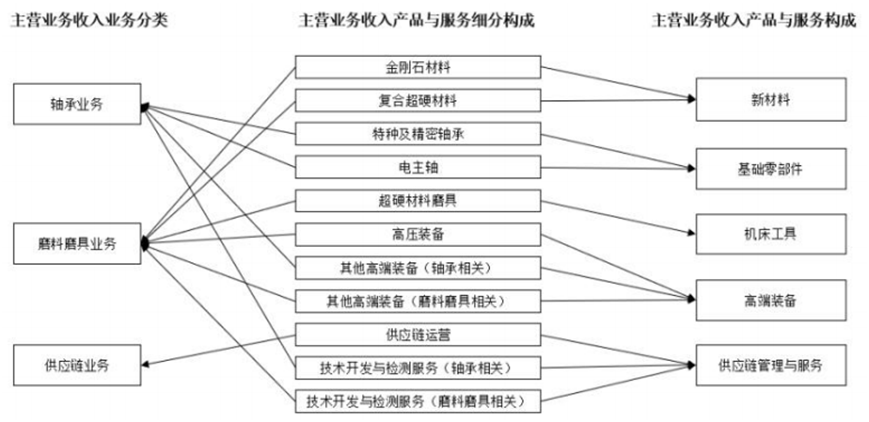

The main business of Guoji Jinggong, source: Guoji Jinggong 2025 Half Year Report

Mastery of Synthesis Technology: Guoji Precision has mastered the two core routes of MPCVD and HPHT. Among them, MPCVD technology has a series of equipment such as 6kW, 10kW, 36kW, and 60kW, covering the complete chain from research and development, small-scale trial production to industrial production, which can meet the production and research and development needs of different scales..

Breakthrough in large-size material technology: It has domestic leading and international advanced level in the growth of large-size single crystal (2-4 inches) and high thermal conductivity polycrystalline diamond films. The single crystal thermal conductivity can reach 1800-2200W/m • K, which has reached the international advanced level and provides key material support for high-end chip heat dissipation.

Equipment independent research and development capability: Guoji Precision is the only listed company that can independently research and produce diamond manufacturing equipment, achieve equipment and material integration, and have the ability to quickly iterate and optimize costs. Compared with other domestic manufacturers that rely on imported equipment, it has more advantages in technology iteration and cost control.