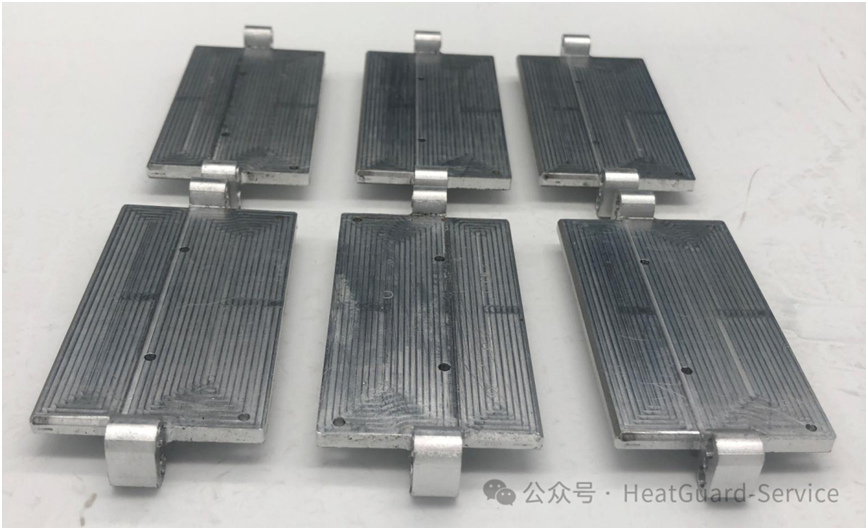

Graphite-aluminum-based solid-state temperature equalizing plate: a practical and effective new heat dissipator

Graphite aluminum based composite solid temperature equalizing plate is a new high-efficiency heat dissipation component.

It uses aluminum as the base, which provides structural support and basic thermal conductivity. At the same time, it contains a composite graphite core material, and the layered structure of graphite is very good. It conducts heat very quickly in its own plane, which can give full play to this advantage.

Unlike traditional phase change temperature equalization plates, this type of equalization plate is designed with a solid-state structure without liquid working fluid inside. With this solid-state structure, heat can be quickly conducted and distributed more evenly.

It combines the characteristics of easy processing of aluminum, strong thermal conductivity of graphite, and stable solid-state structure. In terms of performance and positioning, it falls between traditional metal heat dissipation components and graphite composite heat dissipation materials, and is a mid-range but highly efficient heat dissipation method.

What is the purpose of a temperature averaging plate?

The temperature equalizing plate is actually a component specifically designed for rapid heat dissipation and more uniform heat distribution.

You can think of it as a 'heat transporter'. For example, chips in computers and mobile phones can become hot during operation, and the heat can easily accumulate in a small area. If the temperature is too high, it can affect the performance of the device. At this point, the temperature equalizing plate comes in handy. It can quickly absorb the accumulated heat, then evenly dissipate it, and then discharge the heat through radiators, fans, etc., keeping the components in the equipment at the appropriate temperature and preventing problems due to overheating.

Simply put, its function is to make heat "flow", avoid local temperatures from being too high, and ensure stable operation of the equipment.

Graphite aluminum sandwich structure

The graphite aluminum sandwich structure, as its name suggests, has a structure similar to a sandwich, resembling "two layers of aluminum sandwiching one layer of graphite".

The outermost two layers are made of aluminum material, which has many benefits. It can make the entire structure stronger, less prone to deformation, and is also easy to process. It is relatively easy to make various shapes. The layer sandwiched in the middle is graphite, whether it is natural graphite or artificial graphite. The ability of graphite lies in its fast thermal conductivity, especially in its own plane direction, where heat can run quickly and smoothly.

This "sandwich" combination takes advantage of the stability, ease of processing, and high thermal conductivity of aluminum and graphite. When heat touches it, the graphite in the middle can quickly dissipate the heat, and then transfer it out through the aluminum on both sides. The heat dissipation effect is very good, and the overall structure is stable, making it reliable to use.

The thickness of a conventional graphite aluminum composite temperature equalizing plate is 2mm, and its core graphite aluminum core can be divided into three grades based on the difference in conductivity coefficient, namely 500, 800, and 1100 (unit: W/(m · K)). These three grades of different conductivity coefficients provide gradient selection for the heat dissipation performance of the temperature equalizing plate, which can meet the differentiated requirements for heat conduction efficiency in different scenarios. For example, in the fields of electronic equipment heat dissipation, industrial temperature control, etc., the appropriate grade of graphite aluminum core can be selected according to the specific heat dissipation load and space constraints to achieve efficient temperature equalization and heat dissipation effects.

Figure 1: Structure diagram of graphite aluminum sandwich (upper layer aluminum material); Middle graphite core and lower aluminum material

In addition to the sandwich structure, there is a simpler and more economical structure, which is one layer of aluminum and one layer of graphite.

This structure is very practical to use and has a low cost. It is mainly installed on the radiator and welded onto the fins. Aluminum can provide certain structural support, while graphite is responsible for efficient heat conduction. The combination of the two makes the heat dissipation effect of the fins better, making it particularly suitable for use in such places.