An article analyzes how to choose the thickness of thermal pads, and how significant is the difference between 0.5mm and 1mm?

1

The core logic for selecting the thickness of thermal pads

No.1

Core role

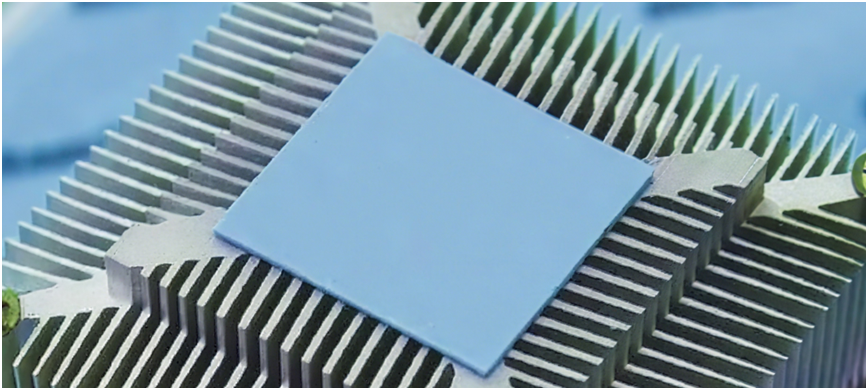

Thermal pads play a crucial role in the cooling system of electronic devices. Take the CPU of a computer as an example. When it runs at high speed, it generates a large amount of heat. If it cannot be dissipated in time, it will cause the CPU temperature to be too high, which will affect the performance of the computer, resulting in lagging or even crashing. And the thermal pad is like a bridge, installed between the heat source (such as chips, graphics cards, etc.) and the heat sink, its core function is to fill the microscopic gap between the two. You can imagine that the surfaces of the heat source and heat sink may appear flat, but at the microscopic level, they are actually uneven, forming air gaps. And air is a poor conductor of heat, with extremely high thermal resistance, like setting up numerous obstacles to heat transfer. The emergence of thermal pads is to eliminate this air and build an efficient heat conduction path, allowing heat to be smoothly transferred from the heat source to the radiator and then dissipated into the surrounding environment.

The selection of its thickness is very knowledgeable and directly affects the balance between "contact thermal resistance" and "material thermal resistance". If the thermal pad is too thin, it cannot fully fill the gap between the heat source and the radiator, resulting in an increase in contact thermal resistance and poor heat transfer, just like a broken part in the middle of a bridge, making it difficult for vehicles (heat) to pass smoothly; However, excessively thick thermal pads will increase the length of the thermal conduction path, leading to an increase in material thermal resistance and a decrease in heat dissipation efficiency. For example, if a bridge is built too long, it will require more time and energy for vehicles to travel. So, only by choosing a suitable thickness of thermal pad can the best heat dissipation effect be achieved, ensuring the stable operation of electronic devices.

No.2

Two core influencing factors

Actual gap measurement: To select a suitable thickness of thermal pad, the first step is to accurately measure the design gap between the heat source and the radiator.. This gap is not simply the distance between two planes, but also takes into account the irregular gap caused by surface roughness. For example, the surface of some chips may have small protrusions or indentations, and the surface of the heat sink is not absolutely smooth, all of which can affect the actual gap size. When measuring, we can use professional measuring tools such as micrometers, profilometers, etc. to ensure the accuracy of the measurement data. Generally speaking, the ideal thickness of a thermal pad is 1-1.2 times the gap value. This is because the thermal pad will experience compression deformation due to certain pressure during installation, and leaving a certain margin can ensure that it can still fully fill the gap after compression.

Material compression characteristics: High quality thermal pads need to have good compression characteristics, usually with a compression rate between 20% and 50%.. This means that under installation pressure, the thermal pad can undergo a certain degree of compression, thereby tightly adhering to the surfaces of the heat source and radiator, eliminating gaps. Meanwhile, good compression characteristics can also prevent excessive compression from causing elastic failure, ensuring that the thermal pad maintains good thermal conductivity throughout long-term use. Taking a 0.5mm thermal pad as an example, it is suitable for filling gaps of 0.3-0.4mm. After being subjected to pressure, its compression rate is between 20% and 40%, which can adapt well to such small gaps; A 1mm gasket is more suitable for gaps of 0.6-0.8mm, with a compression rate of around 20% -30%, and can effectively fill larger gaps. The compression characteristics of thermal pads may vary depending on different application scenarios and devices, and we need to choose according to the actual situation.

2

0.5mm vs 1mm

In the selection of thermal pads, the two common thicknesses of 0.5mm and 1mm may seem like only a tiny difference, but in reality, they have significant differences in performance, installation adaptability, and application scenarios. Below, we will analyze in detail the differences between them.

No.1

Thermal resistance performance

According to Fourier's law of heat conduction, for the same material, thermal resistance (R) is proportional to thickness (d) and inversely proportional to thermal conductivity (k). The calculation formula is R=d/(k × A), where A is the heat transfer area. This is like on a road, the longer (thicker) the road, the greater the resistance (thermal resistance) of the vehicle (heat) to travel; The better the quality of the road (thermal conductivity), the lower the resistance.

A 0.5mm thick thermal pad has significant advantages, with a shorter thermal path and lower thermal resistance. Taking a silicone pad with a thermal conductivity of 8W/(m · K) as an example, it can be calculated that the thermal resistance of a 0.5mm thickness is approximately 0.0625 ℃ · m ²/W, while the thermal resistance of a 1mm thickness doubles to 0.125 ℃ · m ²/W. In high heat scenarios, such as computer GPUs, using 0.5mm thermal pads can effectively reduce chip temperature by 3-5 ℃, which plays an important role in improving GPU performance and stability. Imagine a GPU running like a high-speed factory, generating a large amount of heat. If it cannot be dissipated in a timely manner, it will affect the production efficiency of the factory (GPU performance). The 0.5mm thermal pad is like a shorter and smoother transport channel, which can quickly remove heat and keep the factory running efficiently.

In contrast, 1mm thick thermal pads have certain limitations. Due to the extension of the thermal conduction path, the thermal resistance increases. If the gap inside the equipment is insufficient, such as less than 0.8mm, it is easy to increase the material density due to excessive compression during installation, which further increases the thermal resistance. This is like on an already not very spacious road, where vehicles (heat) become even more congested due to excessive pressure on the road, making it difficult to pass smoothly.

No.2

Installation adaptability

Installation adaptability is also an important factor to consider when selecting the thickness of thermal pads. A 0.5mm thick thermal pad requires extremely high surface flatness, even slight bumps and depressions may cause local gaps, which cannot effectively fill the gaps and affect the heat dissipation effect. Just like laying a tablecloth on a table with an uneven surface, if the tablecloth is too thin, it will be difficult to fully fit the tabletop, resulting in wrinkles and gaps. Therefore, 0.5mm thermal pads usually need to be matched with materials with high flexibility (Shore 00 ≤ 40 hardness) to ensure that they can adapt to small surface undulations and avoid tearing due to uneven stress during installation. It is suitable for precision devices such as mobile SoC, high-frequency memory chips, etc. These devices have extremely high requirements for heat dissipation and compact internal space, requiring lightweight and excellent thermal conductivity gaskets. But its construction difficulty is relatively high, requiring anti-static treatment and precise cutting to ensure the accuracy and stability of installation. This is like installing parts for a precision watch, which requires great care and precision. Even a slight mistake can affect the normal operation of the watch.

A 1mm thick thermal pad has stronger compatibility, covering a gap of 0.6-1.2mm (after compression), suitable for scenarios with larger tolerances, such as industrial power modules, graphics cards, and memory. The surface flatness of these devices is relatively low, and the gaps are also large. A 1mm thermal pad can better adapt to this situation. Moreover, 1mm gaskets have higher mechanical strength, are less prone to damage, and have a high fault tolerance during installation. Even if there are some small deviations, they will not have a significant impact on the heat dissipation effect. This makes it very suitable for mass production and maintenance, as it can improve production efficiency and reduce costs in large-scale production processes. Just like when building large buildings, using stronger and more tolerant materials can make construction easier and easier to maintain in the later stages.

No.3

Differences in Scenario based Applications

Different thicknesses of thermal pads have clear division of labor in practical application scenarios. In devices such as mobile phones, tablet chips, and ultra-thin laptop CPUs, 0.5mm thermal pads are commonly used. These devices pursue extreme slimness, with extremely limited internal space and high requirements for heat dissipation, requiring low thermal resistance thermal pads to ensure rapid heat transfer. For example, the A-series chip heat dissipation of iPhone and the SSD heat dissipation of MacBook Pro both use 0.5mm thermal pads to meet their high-performance and lightweight design requirements. In these scenarios, a 0.5mm thermal pad is like a small and flexible courier, capable of quickly and efficiently transferring heat in narrow spaces.

For desktop graphics cards, video memory, server power modules, and other devices, 1mm thermal pads are more suitable. These devices have relatively large gaps, allowing for a certain degree of surface roughness and placing greater emphasis on high reliability and ease of installation and maintenance. For example, RTX graphics card memory cooling and data center switch modules can use 1mm thermal pads to better fill gaps, ensure stable heat dissipation, and facilitate installation and replacement, reducing maintenance costs. Here, a 1mm thermal pad is like a strong and reliable transporter, capable of stably completing heat transfer tasks in relatively relaxed environments.

3

How to accurately select thickness according to demand?

No.1

Three step selection method

Measuring Gap: Accurate measurement is the first step in selecting the appropriate thickness of the thermal pad.. Use high-precision measuring tools such as micrometers to measure the thickness of multiple points in the contact area between the heat source and the radiator, and then take the average of these measurements. This is because the surfaces of the heat source and radiator are not absolutely flat, and multi-point measurement can more comprehensively reflect the actual gap situation. At the same time, in order to ensure that the thermal pad can fully fill the gap and maintain good elasticity after installation, a compression allowance of 10% -20% needs to be reserved. For example, if the measured average gap is 0.4mm, then choosing a 0.5mm thick thermal pad is more appropriate; If the average gap is 0.8mm, a gasket with a thickness of 1.0mm should be selected. In this way, during the installation process, the thermal pad is compressed and deformed under pressure, and can tightly adhere to the surfaces of the heat source and radiator, effectively eliminating air gaps and improving thermal conductivity efficiency.

Observing working conditions: Different working scenarios have different requirements for thermal pads.. In high heat and precision scenarios, such as the GPU core of a computer, due to its enormous heat generation, it requires extremely high heat dissipation. At the same time, the surface flatness of the GPU core is high, and the gap is relatively small. Therefore, it is preferred to choose a 0.5mm thick thermal pad. Moreover, in order to further reduce thermal resistance, nano silicone or metal based gaskets with a thermal conductivity coefficient of ≥ 10W/(m · K) should be used. These materials have excellent thermal conductivity and can quickly transfer the heat generated by the GPU, ensuring the stability of the GPU during high load operation. In conventional heating scenarios with large tolerances, such as motherboard chipsets, the heat generation is relatively low, the surface flatness is poor, and the gaps are also large. At this point, it is more appropriate to choose a 1mm thick thermal pad, which can better adapt to larger gaps and surface roughness, while balancing filling performance and cost. It is recommended to pair with silicone gaskets with a thermal conductivity of 6-8W/(m · K), which not only meet the heat dissipation needs but also have a high cost-effectiveness.

Check parameters: In addition to clearance and working conditions, the parameters of the thermal pad cannot be ignored.. We should focus on the compression deformation rate and tear resistance strength. The compression deformation rate is the ratio that guides the deformation of a thermal pad under a certain pressure, generally ≤ 10% is preferred. If the compression deformation rate is too high, it indicates that the thermal pad is prone to excessive deformation during use, leading to elastic failure and affecting the heat dissipation effect. The tear resistance strength reflects the durability of the thermal pad, and a tear resistance strength of ≥ 2N/mm can prevent the pad from hardening or breaking due to long-term use. When selecting a thermal pad, check these parameters to ensure that they meet the requirements of the application scenario, thereby ensuring that the thermal pad can work stably for a long time.

No.2

Avoiding pitfalls

Reject the misconception of "thinner is better": When choosing the thickness of a thermal pad, many people have the misconception of "thinner is better", believing that a 0.5mm thermal pad can provide better heat dissipation in any situation.. But in reality, this is not the case. Although the 0.5mm thermal pad has low thermal resistance, its filling capacity is limited. If the gap is greater than 0.6mm and a 0.5mm thermal pad is still forcibly used, it will result in the inability to fill the gap, leading to air residue. And air is a poor conductor of heat, which can significantly increase thermal resistance, and even increase it by more than 50%, seriously affecting heat dissipation efficiency. So, when choosing the thickness of the thermal pad, we cannot blindly pursue thinness, but should make a reasonable choice based on the actual gap situation.

Beware of thickness tolerance traps: Thickness tolerance is an important indicator of thermal conductive gaskets, which directly affects the installation effect and heat dissipation performance of the gasket.. When choosing thermal pads, products with a thickness tolerance of ± 0.05mm should be selected as much as possible, especially for pads with a thickness of 0.5mm, where the tolerance requirements are more stringent. Because the 0.5mm gasket itself is relatively thin, if the tolerance is too large, it will lead to poor local contact. For example, in the heat dissipation of graphics card cores, if the tolerance of the 0.5mm thermal pad is too large, there may be pressure leakage at the edge of the graphics card core, which makes it difficult for heat to be evenly transferred, thereby affecting the performance and stability of the graphics card. So, when purchasing thermal pads, it is important to pay attention to their thickness tolerance to ensure that the product quality meets the requirements.

Surface Treatment Adaptation: The surface treatment of the heat source and heat sink can also affect the selection of thermal pads.. If the surface is relatively rough with a roughness (Ra) greater than 3 μ m, an additional thickness compensation of 0.1-0.2mm is required to ensure that the thermal pad can fully fill the uneven surface and effectively reduce the contact thermal resistance. Alternatively, you can choose a 1mm gasket with a glass fiber reinforcement layer, which not only has good filling properties, but also enhances tear resistance and performs better in applications with rough surfaces. In the heat dissipation of some industrial equipment, due to the high surface roughness of the equipment, using 1mm gaskets with glass fiber reinforcement layer can better meet the heat dissipation requirements and improve the reliability of the equipment.

4

0.5mm vs 1mm Comparison of heat dissipation effects

In order to gain a more intuitive understanding of the performance differences between 0.5mm and 1mm thermal pads in practical applications, we conducted a series of tests. In a 200W GPU testing scenario, we selected different thickness thermal pads of the same material (with a thermal conductivity of 10W/(m · K)) for comparative testing.

No.1

Performance of 0.5mm Thermal Conductive Gasket

In the test, the GPU with a 0.5mm thick thermal pad maintained a stable temperature of 72 ℃ during full load operation. After measurement, its thermal resistance is 0.1 ℃ · m ²/W. This lower thermal resistance value indicates that the 0.5mm thermal pad can effectively reduce the resistance of heat transfer, allowing heat to be quickly transferred from the GPU to the heat sink. During the installation process, the 0.5mm thermal pad compressed to a thickness of 0.45mm under a certain pressure, achieving a compression rate of 10%. This compression ratio is within a reasonable range, ensuring that the thermal pad can tightly adhere to the surface of the GPU and heat sink, eliminating air gaps and improving thermal conductivity efficiency. Meanwhile, through professional testing equipment, we found that its surface adhesion is as high as 98%, almost perfectly filling the gap between the GPU and the heat sink, providing an excellent channel for heat transfer. It's like on a highway, vehicles (heat) can travel at extremely fast speeds because the road (thermal pad) is flat and unobstructed.

No.2

Performance of 1mm Thermal Conductive Gasket

The GPU using a 1mm thick thermal pad reached a full load temperature of 78 ℃, which is 6 ℃ higher than the GPU using a 0.5mm thermal pad. Its thermal resistance is 0.22 ℃ · m ²/W, significantly higher than the thermal resistance of 0.5mm thermal conductive pads. This is because the thickness of the 1mm thermal pad increases, resulting in a longer thermal conduction path and increased resistance to heat transfer. In terms of compression performance, the 1mm thermal pad has a thickness of 0.8mm and a compression rate of 20% after compression under installation pressure. Although the compression rate is within the normal range, due to the large thickness, there may be local uneven stress during the compression process, which affects its surface adhesion. After testing, its surface adhesion was found to be 92%, which is slightly lower than that of the 0.5mm thermal pad. It's like there are some small undulations and bumps on the highway (where the fit is not tight), which will affect the speed of the vehicle (heat) and cause the temperature of the GPU to rise.

No.3

Test Conclusion

From this test data, it can be clearly seen that in precision gap scenarios, the 0.5mm thermal pad, with its advantages of low thickness and low heat dissipation resistance, can significantly reduce the temperature of the GPU, providing strong support for the high-performance operation of the GPU. However, the 0.5mm thermal pad requires extremely high installation accuracy, and requires great care and precision during the installation process. Any small deviation may greatly reduce the heat dissipation effect. Although 1mm thermal pads are not as good as 0.5mm thermal pads in terms of thermal resistance and temperature control, they can adapt to larger gaps and certain surface roughness in conventional scenarios, demonstrating stable performance. At the same time, the installation difficulty of 1mm thermal conductive gaskets is lower, and the cost-effectiveness is better. In some scenarios where high cost and installation convenience are required, it has greater advantages. So, when choosing the thickness of the thermal pad in practice, we need to consider various factors comprehensively based on the specific application scenario and requirements, weigh the pros and cons, and make the most suitable choice.