Jimi&Dangbei laser projector chip heat dissipation upgrade: can phase change paste and graphene gasket replace silicone grease?

The increasing heat consumption of smart projection products is the result of the combined effects of technological upgrades, functional expansions, and evolving user demands. On one hand, to meet users' pursuit of higher image quality, products continuously enhance light source power—shifting from traditional bulbs to LED and laser sources, and even adopting multi-source combined designs to optimize brightness and color. Meanwhile, they incorporate more powerful CPU and GPU chips to support 4K resolution, complex image processing, and intelligent system operation. However, higher-powered light sources and high-performance chips generate more heat during operation;

On the other hand, modern smart projectors are generally equipped with multifunctional modules such as audio systems, wireless screen mirroring, and automatic calibration sensors to enhance the user experience. The additional heat generated by these modules further accumulates. Moreover, to balance portability and aesthetics, the design of the device body has become increasingly compact, compressing internal cooling space and obstructing air circulation, making heat more prone to accumulate. Additionally, as users become more reliant on projectors, prolonged high-load usage scenarios such as extended meetings and movie screenings have increased. Continuous heat generation from the device leads to persistent heat accumulation, ultimately resulting in a significant rise in overall thermal consumption.

For chips with low heat generation (e.g., logic control chips) that prioritize low cost and basic thermal conductivity, traditional thermal paste remains suitable;

If the chip generates moderate heat (such as the main control chip) and requires long-term stability or low-pressure installation, phase change paste is a better choice;

If the chip generates high heat (such as DMD, laser driver chip), requires efficient temperature control or easy maintenance: Graphene gaskets can significantly improve the heat dissipation effect, especially suitable for the core components of high-end laser projectors.

Heat dissipation method of laser projector

The main heating components of intelligent projection products include the main control chip, logic control chip, LED light source or laser light source of the optical part, and DMD chip.

Air cooling: This is the most common method of heat dissipation, which involves installing fans inside the device to dissipate heat through airflow. Fans can blow heat from the heating components towards the heat dissipation fins, increasing the heat dissipation area and improving heat dissipation efficiency. The F7 Pro adopts a split type high-efficiency heat dissipation design, which utilizes modular heat dissipation technology, partition heat dissipation technology, high-performance D10 heat pipes, and the synergistic effect of turbocharged dual fans to build a comprehensive and seamless heat dissipation system.

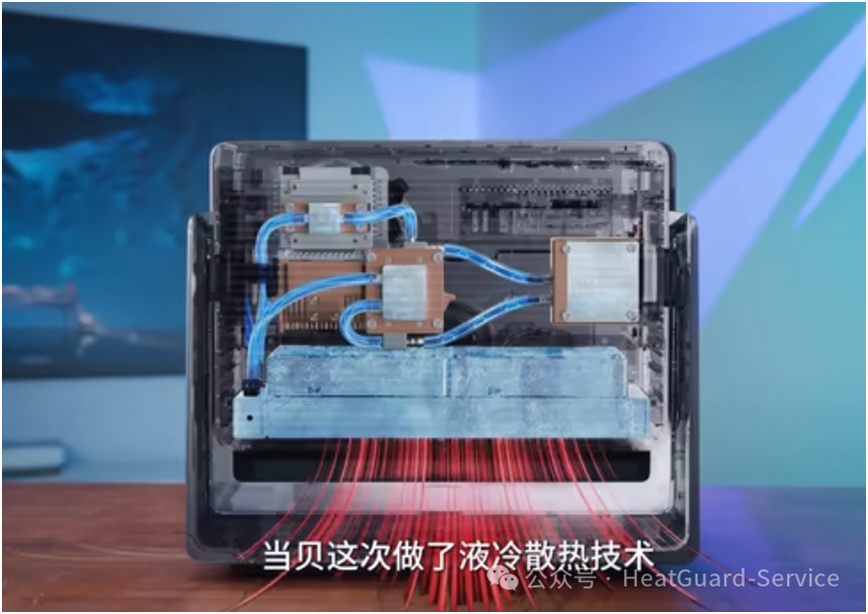

Liquid cooling heat dissipation: This is a relatively new heat dissipation technology that achieves precise heat dissipation for the core heat source through the composite design of liquid cooling pipes and heat dissipation fins. When the Beibei S7 Ultra Max and XGIMI RS20 Pro Max first applied liquid cooling heat dissipation to consumer grade 4K laser projection, their liquid cooling system's heat absorption efficiency increased by 50% compared to traditional air cooling. Under high brightness continuous output, it can effectively avoid performance degradation caused by overheating.

Which chips require silicone grease as the interface material

Master control chip:It is the core processing component of the projector, such as the MediaTek MT9679 chip installed in the Dangbei X5S Pro. During operation, it generates a large amount of heat, which needs to be transferred to the heat sink through thermal grease to ensure its stable operation.

Logic control chip:Responsible for the logical control of various components inside the projector, which also generates heat during operation and requires thermal grease to assist in heat dissipation, ensuring the stable implementation of control functions.

DMD chip:Digital micro mirror devices are the core imaging components of laser projectors that use DLP projection technology. They are composed of millions of micrometer sized lenses, and the high-speed flipping of the lenses during operation generates heat. Thermal grease is usually used between the chip and the metal thermal block to quickly dissipate the heat.

Power supply and LED driver chip:The power chip is used to convert the input power into the voltage and current required by various components of the projector, while the LED driver chip is responsible for driving the light source of the laser projector. Both generate a lot of heat during operation, and thermal grease is often used for heat dissipation to prevent overheating from affecting performance or causing damage.

Is there a better interface material besides silicone grease

Phase change paste: suitable for low to medium heat generating chips, balancing "low pressure" and "long-term stability"

Phase change paste is a thermal interface material that is in a solid state at room temperature and transforms into a semi fluid state after reaching a specific temperature (phase change temperature, 45 ℃). Its core advantages lie in "adapting to low-pressure installation scenarios" and "solving the long-term problem of silicone grease", especially suitable for chips that are sensitive to installation pressure or require long-term stable heat dissipation.

Applicable chip types

Main control chip(such as MT9679):Medium heating power (usually 10-20W), and the chip packaging is mostly BGA/BGA. During installation, the pressure of the heat sink on the chip needs to be controlled (to avoid pressure damage to the solder joints). The phase change paste is easy to assemble in solid state and can fill the interface gaps after phase change, so there is no need to worry about chip damage caused by excessive pressure.

Logic control chip:with low heating power (5-10W), it does not require high thermal conductivity efficiency, but needs to be stable for a long time (to avoid heat dissipation failure caused by silicone grease drying and shrinking). The thermal conductivity layer formed by phase change paste has strong stability and a service life of up to 5-8 years (far exceeding the 2-3 years of silicone grease).

Power/LED driver chips:Some use surface mount packaging, with compact installation space. Phase change paste does not need to be applied (can be prefabricated into gasket form), which can reduce thermal conductivity failure caused by uneven application. Moreover, high temperature resistance (some models have a temperature resistance of ≥ 150 ℃) is suitable for the high-temperature working environment of the driver chip.

No overflow, easy to assemble:It is solid at room temperature and will not contaminate chip pins due to excessive overflow like silicone grease, especially suitable for precision packaged chips (such as peripheral capacitors and resistors of main control chips).

Long term stability:The thermal conductive layer formed after phase change is not easy to oxidize or dry shrink, avoiding a decrease in thermal conductivity efficiency after long-term use of silicone grease (usually the silicone grease needs to be replaced after 1-2 years, and the phase change paste can support the life cycle of the whole machine).

Low pressure adaptation:No need to rely on heat sink pressure to fill gaps (after phase transition, it can be filled with its own fluidity), protecting fragile chip packaging (such as the micro mirror structure of DMD chips, which can cause lens displacement if pressure is too high).

Comparison of Three Types of Interface Materials

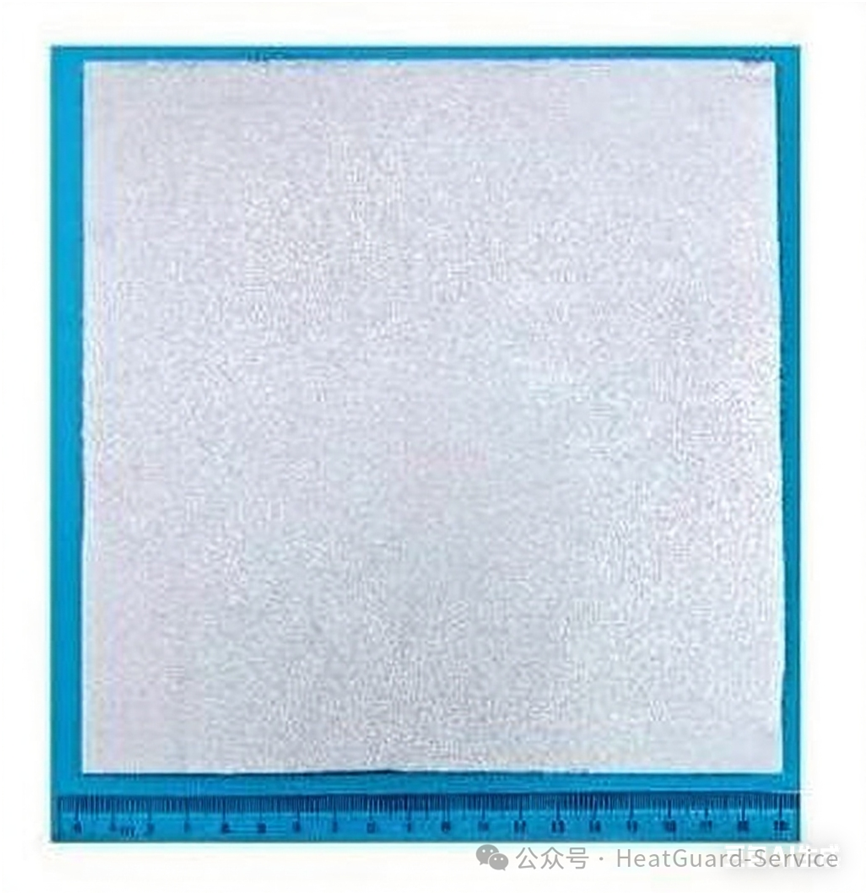

This product is prepared by controllable foaming of graphene paper and surface metallization process of high-temperature treatment machine, with the characteristics of no volatile components, no powder shedding, and excellent compatibility with non white oil. As an alternative to metal indium sheets, it can be widely used in deep low-temperature Dewar scenarios, not only effectively avoiding the problem of "cold welding", but also facilitating the cleaning of the contact surface after disassembly, significantly improving the convenience and reliability of use.

- Electrical properties: possessing conductivity;

- Thermal properties:

- Thermal conductivity:130 W/m・K

- Interface thermal resistance:0.1 K・cm²/W

- Structural non mechanical properties:

- Metal melting point:120℃

- Thickness range:0.1mm - 0.25mm

- Compression amount:20%

- Density:0.5 g/cm³