What exactly is thermal management? This article will turn you from a "thermal novice" into an "expert"

Thermal Management: What the hell is it?

Simply put, thermal management is the process of adjusting and controlling the temperature or temperature difference of a specific object using heating or cooling methods according to its requirements. This includes three key elements: specific objects, such as mobile phone chips, computer CPUs, as well as batteries, motors, etc. that we mentioned earlier; Implementation methods, such as fans, heat sinks, liquid cooling systems, etc; There are also thermal management parameters, mainly temperature and temperature difference.

The implementation of thermal management involves three basic principles of heat transfer, namely thermal conduction, convective heat transfer, and thermal radiation. Thermal conductivity is easy to understand, which refers to the transfer of heat through direct contact. For example, when we stir hot water with a metal spoon, the spoon will become hot, and this is the phenomenon of thermal conductivity. Convective heat transfer is the process of removing heat through fluid flow. When we open a computer case, we can see the fan rotating, driving air flow and taking away heat. This is how convective heat transfer works. And thermal radiation is the emission of energy in the form of electromagnetic waves, and the transfer of heat from the sun to the earth is through thermal radiation. In general, radiative heat transfer accounts for a relatively small proportion in the thermal management of electronic devices, so most designs mainly consider two methods: thermal conduction and convection.

After understanding the concept and principles of thermal management, I believe you will have this question in your mind: why is thermal management so important? In fact, thermal management plays a crucial role in our daily lives and various technological applications, mainly reflected in the following aspects.

No.1

Prevent overheating and system failures

During the operation of electronic devices, heat is inevitably generated due to factors such as current flow and component resistance. If these heat cannot be dissipated in a timely manner, it will cause the component temperature to be too high. When the temperature of a component exceeds its normal operating range, it may cause performance degradation, such as when the CPU temperature of a computer is too high after running large games for a long time, which can cause game graphics to freeze. More seriously, sustained high temperatures may cause permanent damage to components, just like when charging a mobile phone, if it overheats, it may damage the battery and even lead to more dangerous situations. The existence of a thermal management system is like installing a "temperature guard" on electronic devices, which can timely and effectively dissipate heat, prevent performance problems or damage to components due to overheating, and ensure the stable operation of the equipment.

No.2

Improve device performance and lifespan

Taking our daily use of smartphones as an example, due to their compact internal structure, the gaps between various components are very small. When we use our mobile phones for high load operations such as playing games and shooting videos, the processor and battery generate a large amount of heat. If these heat cannot be dissipated in a timely manner, it will affect the temperature of other components and break the original coordinated working state between hardware. In this case, the phone may experience slower running speed, automatic decrease in screen brightness, and other phenomena, which not only affect device performance, but also shorten the service life of the phone if it is in this high temperature state for a long time. By implementing reasonable thermal management measures, such as using heat sinks, heat pipes, and other heat dissipation devices, the internal temperature of the phone can be effectively reduced, and the hardware can be maintained in good working condition, thereby improving device performance and extending the service life of the device.

No.3

Security Protection

In new energy vehicles and energy storage systems, thermal management is directly related to the safety of the system. Take energy storage power plants as an example, as their scale continues to expand and their power increases, they accumulate a large amount of heat during operation. If these heat cannot be dissipated in time, it may lead to uncontrolled heat generation. Thermal runaway is a very dangerous situation that can cause battery short circuits, bulges, and even explosions, posing a serious threat to personnel and property safety. In new energy vehicles, if the battery thermal management is improper, overheating of the battery during charging or driving may also cause serious accidents such as fires. Therefore, an effective thermal management system is crucial for ensuring the safe operation of new energy vehicles and energy storage systems.

No.4

Improve energy efficiency

In new energy vehicles, the operating temperature of the battery has a significant impact on its performance, which in turn affects the vehicle's range. When the temperature of the battery is too high or too low, the internal chemical reaction rate will change, resulting in an increase in the internal resistance of the battery and a decrease in charging and discharging efficiency. For example, in the cold winter, the range of electric vehicles often shrinks significantly because low temperatures affect the performance of the battery. A reasonable thermal management strategy can maintain the working temperature of the battery within a reasonable range through heating or cooling methods, thereby reducing battery energy consumption, improving energy utilization efficiency, and reducing vehicle operating costs. Some new energy vehicles adopt heat pump technology for thermal management systems, which can use the waste heat generated by batteries to heat the interior of the vehicle in winter, not only improving energy utilization efficiency, but also increasing driving range.

2

The main technical means of thermal management

Thermal management technology, as the key to ensuring stable operation and improving performance of equipment, has formed a complete and rich technical system after years of development. According to whether external energy input is required, thermal management technology is mainly divided into two categories: passive cooling technology and active cooling technology. They each play an important role in different application scenarios with their unique principles and advantages.

No.1

Passive cooling technology

Passive cooling technology does not require external energy input and can achieve heat dissipation solely based on its own characteristics. It has significant advantages such as simple structure, high reliability, and low maintenance costs. Passive cooling technology is often the preferred solution in scenarios where heat dissipation requirements are relatively low or extreme reliability is sought after.

A heat sink is one of the most common components in passive cooling technology, serving as an efficient heat collector. Usually made of high thermal conductivity materials such as aluminum or copper, these materials have excellent thermal conductivity and can quickly transfer heat from the heat source to themselves. The working principle of a heat sink is based on a simple yet effective physical phenomenon: increasing the surface area can improve heat dissipation efficiency. Through clever design, the heat sink is made into various shapes, such as fins, columns, etc., to maximize the contact area with the air. When heat is transferred to the surface of the heat sink, it will be dissipated to the surrounding environment through natural convection and thermal radiation. In the heat sink of a computer CPU, we can see rows of dense metal fins, which are heat sinks that can quickly dissipate the large amount of heat generated by the CPU, ensuring that the CPU operates within the normal temperature range.

The thermal interface material is like a bridge connecting the heat source and heat dissipation components, used to fill the tiny gaps between the two surfaces. In electronic devices, there are many tiny air gaps between heating elements (such as chips) and heat sinks or device casings, although they appear to be in close contact. And air is a poor conductor of heat, and these tiny gaps can greatly hinder the transfer of heat, forming a high thermal resistance. Thermal interface materials have high thermal conductivity, which can effectively fill these small gaps, reduce thermal resistance, and facilitate the smooth transfer of heat from the heat source to the heat dissipation components. Common thermal interface materials include thermal conductive silicone, thermal conductive pads, etc. Thermal conductive silicone is a viscous material that can tightly adhere between the heating element and the heat sink, ensuring good thermal contact; Thermal pads have a certain degree of flexibility and can be attached to heating elements of different shapes. They can also cushion the stress caused by thermal expansion and contraction between heating elements and heat dissipation components. In smartphones, thermal conductive silicone is widely used between chips and heat sinks, effectively improving heat dissipation and ensuring stable performance of the phone.

Phase change materials are magical substances that can absorb or release heat when transitioning between solid and liquid states, effectively controlling temperature fluctuations. The working principle of phase change materials is based on their unique physical properties: during the phase change process, the material absorbs or releases a large amount of latent heat while the temperature remains relatively constant. When the ambient temperature rises, phase change materials will transform from solid to liquid, absorbing a large amount of heat during this process, thereby suppressing the temperature rise; When the ambient temperature drops, phase change materials will transition from liquid to solid, releasing the heat they previously absorbed to prevent excessive temperature drop. In the battery thermal management system of new energy vehicles, phase change materials can be installed around the battery module. When a large amount of heat is generated during battery charging or discharging, phase change materials will melt and absorb the heat to avoid excessive battery temperature; In low-temperature environments, the solidification of phase change materials releases heat, which helps to improve the performance of batteries.

No.2

Active cooling technology

Active cooling technology requires external energy input, but its heat dissipation efficiency is usually higher, which can meet more complex and demanding heat dissipation requirements. Active cooling technology plays an indispensable role in some high-performance devices, such as servers in data centers and high-performance computers.

Fans and blowers are the most common devices in active cooling technology, which enhance heat dissipation by forcing air convection. The working principle of a fan is very simple. When the motor drives the fan blades to rotate, it generates airflow, which quickly flows over the surface of the heating component. In this way, the heat will be carried away by the flowing air, thus achieving the purpose of heat dissipation. In a computer case, we can see multiple fans, some of which are responsible for drawing cold air into the case, while others are responsible for expelling hot air from the case, creating effective air circulation to ensure that the hardware devices inside the case can be kept within the appropriate temperature range.

Blowers are similar to fans, but they typically have larger blades and higher speeds, which can generate greater air volume and higher air pressure. The main purpose of a blower is to increase air flow, and it has a wide range of applications in industrial ventilation, large equipment heat dissipation, and other fields. In some large data centers, due to the large number of servers and the enormous heat generated, the cooling capacity of ordinary fans may not be able to meet the demand. In this case, it is necessary to use blowers to provide stronger air flow to ensure the stable operation of the data center.

Liquid cooling system is an efficient heat dissipation method that takes away heat through liquid circulation, and its heat dissipation efficiency is much higher than that of air cooling. The working principle of liquid cooling systems is based on the high thermal conductivity and high specific heat capacity characteristics of liquids. In liquid cooling systems, a closed loop is usually composed of a cold drain, water pump, water pipe, and coolant. When the equipment is running, the heat generated by the heating components is transferred to the cold head in close contact with the heating source through thermal conduction. The coolant flows through the cold head under the drive of the water pump, absorbs the heat and rises in temperature. It then flows through the water pipe to the cold exhaust, where the heat is dissipated into the surrounding air. The cooled coolant flows back to the cold head, forming a circulating heat dissipation process. In high-performance computers, liquid cooling systems are widely used for cooling CPUs and GPUs. Through the liquid cooling system, the large amount of heat generated by these high-performance chips can be quickly and effectively carried away, ensuring the stability of the chips during high load operation, thereby improving the overall performance of the computer.

Peltier devices, also known as semiconductor refrigeration chips, work based on the Peltier effect. When current passes through a junction composed of two different semiconductor materials, a temperature difference is generated at both ends of the junction, with one end absorbing heat and the other end releasing heat. Peltier devices utilize this characteristic to transfer heat from one side to the other, achieving cooling or heating effects. In some small electronic devices, such as portable refrigerators, small refrigeration cabinets, etc., Peltier devices are used as refrigeration components. By controlling the direction and magnitude of the current, the cooling or heating effect can be accurately adjusted. In some high-end smartphones, Peltier devices have also been used to assist in heat dissipation. When the phone heats up, the Peltier device can transfer the heat from the inside of the phone to the outside, effectively reducing the temperature of the phone and improving the user experience.

3

The widespread application of thermal management in daily life

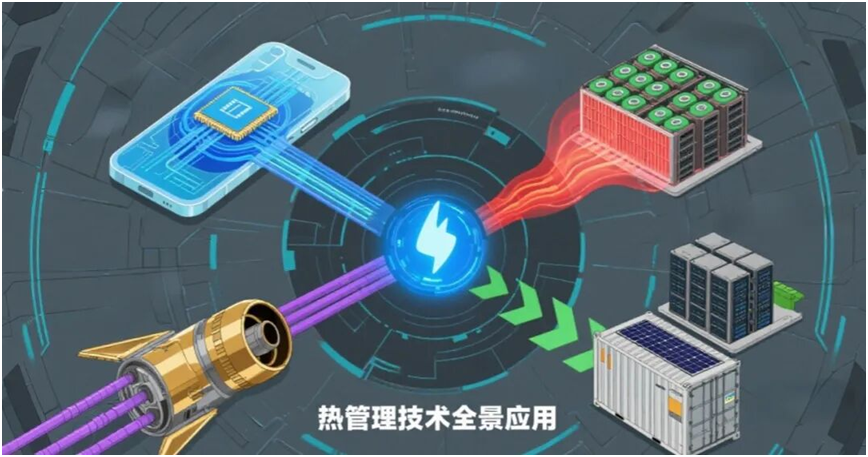

Thermal management technology, as a key to ensuring stable operation and improving performance of various equipment, has been widely integrated into all aspects of our lives, playing an indispensable role in many fields such as consumer electronics, new energy vehicles, data centers, energy storage systems, aerospace, and more.

No.1

Consumer Electronics

Nowadays, consumer electronics have become an indispensable part of our lives, from smartphones to laptops, from tablets to game consoles. While these devices bring us convenience and entertainment, they also face the problem of overheating. Taking mobile phones as an example, when we play large games, edit videos, or open multiple applications for a long time, the phone chip will run at full capacity, generating a large amount of heat. If these heat cannot be dissipated in a timely manner, the chip will trigger a frequency down protection mechanism due to overheating, causing the phone to run slower and the screen to lag, seriously affecting the user experience.

To address these issues, engineers have adopted various thermal management solutions. A heat sink is a common heat dissipation component, usually made of high thermal conductivity materials such as aluminum or copper, which improves heat dissipation efficiency by increasing the surface area. Inside the phone, we can see a thin metal sheet tightly attached to the chip, which is the heat sink. It can quickly conduct the heat generated by the chip and dissipate it into the surrounding air. A heat pipe is also an efficient heat dissipation device that utilizes the principle of liquid absorbing and releasing heat during evaporation and condensation, quickly transferring heat from the high-temperature end to the low-temperature end. In laptops, heat pipes are widely used as they can transfer the heat generated by the CPU and GPU to the heat dissipation fins, and then blow the heat out of the computer through a fan, ensuring the stability of the computer during high load operation.

In recent years, graphene films have also gradually emerged in the field of consumer electronics. Graphene is a two-dimensional material composed of carbon atoms, which has excellent thermal conductivity, with a thermal conductivity several times that of copper. Graphene film can be made into ultra-thin sheets and attached to the surface of chips or other heating components, which can quickly and evenly disperse heat, effectively reduce local temperature, and improve heat dissipation effect. Some high-end smartphones and laptops have started using graphene film as a heat dissipation material, bringing users a smoother user experience.

No.2

New Energy Vehicles

The importance of thermal management in the field of new energy vehicles is self-evident. The core components of new energy vehicles - batteries, motors, and electronic control systems - generate a large amount of heat during operation. The optimal operating temperature for lithium-ion batteries is usually between 20-40 ℃. If the temperature is too low, the viscosity of the electrolyte inside the battery increases, the migration of lithium ions is hindered, resulting in an increase in internal resistance and a sharp decline in charging and discharging performance. The range of electric vehicles will be greatly reduced, and lithium deposition may occur during the charging process, posing a safety hazard; When the temperature is too high, the chemical reactions inside the battery intensify, the number of side reactions increases, and the battery capacity decay accelerates. Long term high temperatures may cause uncontrolled heating, leading to serious accidents such as fires and explosions.

To ensure that the battery is always within the optimal operating temperature range, new energy vehicles typically use liquid cooling systems. The liquid cooling system arranges coolant pipes inside the battery pack to circulate and remove the heat generated by the battery. The coolant is generally a mixture of ethylene glycol and water, which has good heat dissipation and antifreeze properties. The Tesla Model 3 adopts a liquid cooled battery thermal management system, which effectively maintains the temperature consistency of the battery and improves its performance and safety by precisely controlling the flow and temperature of the coolant.

Heat pump air conditioning is also an important component of the thermal management system in new energy vehicles. Heat pump air conditioning can transfer external heat into the car during winter to provide heating, while also heating the battery to improve its performance in low-temperature environments; In summer, the cooling function can be achieved to create a comfortable driving environment inside the car. Compared to traditional resistance heating methods, heat pump air conditioning has higher energy efficiency and can significantly improve the range of new energy vehicles in winter.

Phase change materials have also been applied in thermal management of new energy vehicles. Phase change material is a material that can absorb or release a large amount of heat when transitioning between solid and liquid states. When the temperature of the battery rises, the phase change material will transform from solid to liquid, absorb heat, and thus control the increase in battery temperature; When the battery temperature drops, the phase change material will transform from liquid to solid, releasing heat and preventing the battery temperature from being too low. The application of phase change materials can effectively reduce fluctuations in battery temperature and extend battery life.

No.3

Data Center

With the rapid development of information technology, data centers bear the responsibility of storing and processing massive amounts of data. The high-density servers in the data center generate a large amount of heat during operation. If the heat dissipation problem is not effectively solved, it will not only affect the performance and stability of the servers, but also increase energy consumption, and even lead to server failures and data loss. According to statistics, about 40% of the energy consumption in data centers is used for heat dissipation.

In order to solve the heat dissipation problem of high-density servers, data centers have adopted various thermal management technologies, among which cold plate liquid cooling and immersion liquid cooling are common solutions. Cold plate liquid cooling is the installation of cold plates on key heating components of servers, such as CPUs, GPUs, etc. The cold plates have cooling liquid channels inside, which take away heat through the circulation of cooling liquid. Cold plates are usually made of metal materials such as copper or aluminum, which have good thermal conductivity. The advantages of a cold plate liquid cooling system are easy installation, minimal modifications to existing server architecture, and suitability for most data centers.

Immersion liquid cooling is the process of completely immersing the server in coolant, which comes into direct contact with the heating components and carries away the heat. The coolant used in immersion liquid cooling is usually insulated and will not cause damage to electronic components. This heat dissipation method has extremely high heat dissipation efficiency, which can effectively reduce the temperature of the server and improve its performance and reliability. Meanwhile, due to the high specific heat capacity of the coolant, it can absorb more heat, thus reducing the number and energy consumption of heat dissipation equipment. The data centers of some large Internet companies have begun to use immersion liquid cooling technology, which has achieved significant energy saving and heat dissipation effects.

No.4

Energy storage system

Energy storage systems, as key equipment for storing and releasing electrical energy, play an important role in renewable energy grid integration, power grid peak shaving, and other aspects. However, the batteries in the energy storage system generate heat during the charging and discharging process. If the heat is not dissipated in a timely manner, it can lead to an increase in battery temperature, accelerate battery aging, and even cause thermal runaway, affecting the safety and service life of the energy storage system.

In order to avoid battery thermal runaway and extend battery life, energy storage systems usually adopt thermal management solutions such as liquid cooling systems, phase change materials, and air cooling. The application principle of liquid cooling system in energy storage system is similar to that of new energy vehicles, which takes away the heat generated by the battery through the circulation of coolant and maintains the stability of battery temperature. Phase change materials can absorb or release heat when the battery temperature changes, playing a buffering role and reducing the impact of temperature fluctuations on the battery. Air cooling is the process of forcing air flow through a fan to remove heat from the surface of the battery. Air cooling systems have a simple structure and low cost, but their heat dissipation efficiency is relatively low. They are usually suitable for energy storage systems with lower power.

In some large energy storage power plants, multiple thermal management technologies are often used comprehensively to achieve the best heat dissipation effect. The main heat exchange is carried out through a liquid cooling system, assisted by phase change materials to control temperature fluctuations, and combined with an air cooling system for auxiliary heat dissipation, ensuring the safe and stable operation of the energy storage system under various working conditions.

No.5

Aerospace

In the aerospace industry, thermal management is crucial for ensuring the reliability of electronic systems in extreme environments. When an airplane is flying at high altitude, the external environment temperature is extremely low, and electronic devices generate a large amount of heat during operation, requiring timely heat dissipation; Spacecraft in space face extreme environments such as vacuum, alternating high and low temperatures, and strong radiation, which place higher demands on thermal management systems.

To address these challenges, the aerospace industry has adopted thermal management solutions such as advanced thermal conductive materials and efficient circulation systems. Advanced thermal conductive materials such as carbon fiber composite materials and ceramic based composite materials have the advantages of light weight, high strength, and good thermal conductivity. They can effectively conduct heat while reducing the weight of aircraft. In satellite electronic devices, carbon fiber composite materials are often used to make heat dissipation structural components, which quickly transfer the heat generated by the equipment.

Efficient circulation systems achieve heat transfer and exchange through the circulation of liquids or gases. In aircraft avionics, a liquid cooling circulation system is commonly used, where the coolant circulates in a closed pipeline, taking away the heat generated by the electronic equipment and dissipating it to the outside air through a heat exchanger. This circulatory system has the advantages of high heat dissipation efficiency and strong reliability, which can ensure the normal operation of electronic devices in complex flight environments.

Some spacecraft also use thermal radiators to dissipate heat. A radiator is a device that uses the principle of thermal radiation to dissipate heat into space. It is usually made of high emissivity materials and can radiate the heat inside the spacecraft in the form of electromagnetic waves, thereby achieving the purpose of heat dissipation.

4

The Future Direction of Thermal Management Technology

No.1

Integration and Intelligence

With the rapid development of technology, thermal management systems are increasingly showing a significant trend towards integration and intelligence, as if endowing devices with a "smart brain" and an "efficient collaborative body". This trend is particularly evident in the field of new energy vehicles. Through intelligent algorithms, the thermal management system can provide personalized temperature control services based on various factors such as users' daily travel habits, real-time vehicle conditions, and environmental temperature. For example, some advanced thermal management systems for new energy vehicles can predict users' travel time and itinerary based on their long-term travel data. Before the user departs, the system will automatically preheat or cool the battery in advance to ensure that it operates at the optimal temperature. In this way, not only does it improve energy efficiency and reduce energy consumption, but it also effectively extends the service life of the battery, enhances the overall performance of the vehicle, and improves the driving experience for users.

In the data center, an integrated thermal management system can integrate functions such as server cooling and room environment control, and achieve precise temperature control of the data center through intelligent monitoring and adjustment. When the server load and heat generation increase, the system can automatically adjust the power of the cooling equipment, increase the cooling capacity, and ensure that the server always operates at a suitable temperature. The intelligent thermal management system can also achieve fault prediction and automatic diagnosis. Through real-time analysis of system operation data, potential fault hazards can be detected in advance, and timely measures can be taken to repair them, greatly improving the reliability and stability of data centers.

No.2

Multi scenario application expansion

Thermal management technology is no longer limited to traditional consumer electronics and automotive fields, but is actively expanding into new scenarios such as data centers, energy storage systems, and humanoid robots, demonstrating strong adaptability and broad application prospects. Taking data centers as an example, with the surge in demand for artificial intelligence computing power, the power density of single cabinets in data centers continues to rise, and traditional air cooling technology is no longer able to meet the growing demand for heat dissipation. Liquid cooling technology has gradually become the mainstream solution for high-density data centers due to its efficient heat dissipation and temperature uniformity. Direct cooling (such as cold plate liquid cooling) and immersion liquid cooling can achieve energy-saving effects with a power utilization efficiency (PUE) of less than 1.1 by directly contacting the cooling liquid with the heating components, greatly reducing the energy consumption of data centers. Leading companies such as Alibaba Cloud and Tencent have deployed liquid cooling systems on a large scale in newly built data centers, effectively solving the heat dissipation problem of high-density servers and improving the operational efficiency and reliability of data centers.

In energy storage systems, thermal management technology is crucial for ensuring the safety and performance of batteries. With the rapid development of renewable energy, the scale and application scope of energy storage systems are constantly expanding. In order to avoid battery thermal runaway and extend battery life, energy storage systems need to be equipped with efficient thermal management systems. Technologies such as liquid cooling systems, phase change materials, and air cooling have been widely used in energy storage systems. Through precise control of the thermal management system, the temperature stability of the battery during charging and discharging can be ensured, improving the safety and stability of the energy storage system.

As an emerging technology field, humanoid robots also pose new demands for thermal management technology. During the movement of humanoid robots, components such as motors and controllers generate a large amount of heat. If these heat cannot be dissipated in a timely manner, it will affect the performance and lifespan of the robot. Thermal management technology can effectively solve the heat dissipation problem of humanoid robots by optimizing the heat dissipation structure and using efficient heat dissipation materials, ensuring their stable operation in various complex environments.

No.3

Application of New Materials

The continuous emergence of new materials has injected strong impetus into the advancement of thermal management technology, as if opening a door to a new realm in the field of thermal management. High thermal conductivity materials such as graphene and metal matrix composites, as well as new materials such as phase change materials and carbon nanotubes, are showing great potential in the field of thermal management due to their unique performance advantages.

Graphene, as a two-dimensional material composed of carbon atoms, has excellent thermal conductivity, with a thermal conductivity several times that of copper. Graphene film can be made into ultra-thin sheets and attached to the surface of chips or other heating components, which can quickly and evenly disperse heat, effectively reduce local temperature, and improve heat dissipation effect. Graphene film has been widely used in consumer electronics products such as smartphones and tablets, providing users with a smoother user experience.

Metal based composite materials combine the advantages of metals and reinforcing materials, and have characteristics such as high thermal conductivity, high strength, and low density. In the aerospace field, metal based composite materials are used to manufacture thermal management components for aircraft, which can effectively conduct heat while reducing weight, ensuring the normal operation of electronic devices in extreme environments.

Phase change materials also play an important role in the field of thermal management. It can absorb or release a large amount of heat during the transition between solid and liquid states, effectively controlling temperature fluctuations. In the battery thermal management system of new energy vehicles, phase change materials can be installed around the battery module. When the temperature of the battery rises, the phase change material will melt and absorb heat, avoiding excessive battery temperature; In low-temperature environments, the solidification of phase change materials releases heat, which helps to improve the performance of batteries.

Carbon nanotubes, as a new type of nanomaterial, have extremely high aspect ratios and excellent thermal conductivity. Adding carbon nanotubes to traditional thermal management materials can significantly improve their thermal conductivity and mechanical properties. In the field of heat dissipation for electronic devices, carbon nanotube composite materials have shown promising application prospects.

No.4

Green and Efficient

Against the backdrop of actively promoting carbon neutrality goals globally, the trend of thermal management systems developing towards green and efficient direction is becoming increasingly evident. This is not only a demand of the times, but also an inevitable choice for the coordinated development of technological progress and environmental protection. The use of lightweight materials and efficient heat pump technology has become a key path for thermal management systems to reduce energy consumption and carbon emissions.

The application of lightweight materials can effectively reduce the weight of equipment, thereby reducing energy consumption. In new energy vehicles, the use of lightweight materials such as aluminum alloy and magnesium alloy to manufacture components of the thermal management system, such as radiators and cooling pipes, can not only reduce the weight of the vehicle and improve its range, but also reduce energy consumption and carbon emissions during the production process.

Efficient heat pump technology is an important means for achieving green and efficient thermal management systems. Heat pump technology is based on the principle of reverse Carnot cycle, which can transfer heat from low-temperature environment to high-temperature environment, achieving the functions of cooling and heating. Compared with traditional resistance heating and compression refrigeration technologies, heat pump technology has a higher energy efficiency ratio. In winter, heat pumps can transfer heat from the external environment to vehicles or buildings for heating purposes, while reducing reliance on traditional fossil fuels and lowering carbon emissions. In summer, heat pumps can operate in reverse to achieve cooling function and improve energy utilization efficiency.

Some advanced thermal management systems also adopt energy recovery technology to recover and utilize the waste heat generated during equipment operation. In the data center, the waste heat generated by servers is recovered through heat exchangers for preheating domestic water or heating buildings, achieving cascading energy utilization and further improving energy efficiency, reducing energy waste.

5

Tips for Thermal Management in Daily Life

After understanding the importance and technical means of thermal management, we can also pay attention to the thermal management of equipment in daily life through some simple methods, so that the equipment can operate more stably and extend its service life.

No.1

Keep electronic devices well ventilated

Electronic devices generate heat during operation, and good ventilation is the key to heat dissipation. When using mobile phones, laptops, and other devices, avoid placing them on soft surfaces such as beds or sofas. These soft surfaces can easily clog the ventilation openings of the device, like putting a "tightening spell" on the device, hindering heat dissipation and causing the device temperature to rise. We should place the equipment in a hard, flat, and well ventilated place, such as a table, so that the equipment can "breathe" freely, dissipate heat in a timely manner, and maintain normal working temperature.

No.2

Regularly clean the heat dissipation components

Computer fans, air conditioning filters, and other heat dissipation components are prone to accumulate dust and debris after prolonged use. This dust acts as a layer of insulation, reducing the heat dissipation efficiency of the components. Regular cleaning of heat dissipation components is an important measure to maintain good heat dissipation performance of equipment. For computer fans, we can use a compressed air tank to blow off the dust on the fan blades, or we can use a soft bristled brush to gently clean them; The air conditioning filter can be periodically removed, rinsed with clean water, dried, and then reinstalled. By regularly cleaning the cooling components, the cooling system of the equipment can be kept unobstructed, ensuring that the heat generated during operation can be dissipated in a timely manner, and improving the stability and reliability of the equipment.

No.3

Avoid high-intensity use while charging

When charging electronic devices, if high-intensity usage is carried out simultaneously, such as playing large games, watching high-definition videos, etc., the device's processor and battery will be in a high load working state at the same time, leading to increased heating of the device. In the long run, this not only affects the lifespan of the battery, but may also cause damage to other hardware of the device. Therefore, we should try to avoid using the device with high intensity while charging. If you need to use the device, it is best to do it after charging is complete, or choose low-power operations during charging, such as viewing documents, browsing the web, etc., to reduce the device's heat generation and protect its performance and lifespan.

No.4

Pay attention to the working environment temperature of the equipment

Electronic devices have their suitable working environment temperature range, and beyond this range, the performance of the device may be affected. Especially lithium battery devices are more sensitive to temperature. In high temperature environments, the chemical reaction rate of lithium batteries will accelerate, leading to capacity degradation and even potential safety issues; In low-temperature environments, the internal resistance of the battery will increase, the charging and discharging performance will decrease, and the endurance of the device will be significantly reduced. Therefore, we should try to avoid using electronic devices in extreme temperature environments. In the hot summer, do not expose the equipment to sunlight or high temperature inside the car for a long time; In the cold winter, try not to use the equipment outdoors for a long time. If it must be used, take measures to keep the equipment warm.

No.5

Pay attention to abnormal heating of devices

If the device experiences abnormal heating, it may be a precursor to a malfunction and requires our timely attention and inspection. When the device suddenly heats up severely under normal use, or when the heating situation is significantly different from usual, we should immediately stop using the device and let it cool down. Then check if there are any software malfunctions in the device, such as if any programs are running abnormally, occupying a large amount of system resources and causing overheating; You can also check if there are any hardware issues with the device, such as whether the cooling fan is functioning properly and if there are any damaged components. If you are unable to determine the cause of the malfunction, it is best to send the equipment to a professional repair shop for inspection and maintenance to avoid further use of the equipment in a faulty state, which may cause more serious damage.

Thermal management, this seemingly obscure and professional field, is actually closely related to our lives and occupies a pivotal position in many industries. From everyday consumer electronic devices to new energy vehicles that lead future travel; From data centers carrying massive amounts of data to energy storage systems driving energy transformation, thermal management technology is ubiquitous, silently guarding the stable operation of various devices and ensuring the convenience and efficiency of our lives.