Nobel Prize-level achievement! A major breakthrough has been made in the world-renowned challenge of high thermal conductivity composite materials, with multiple papers published in top journals, shoc

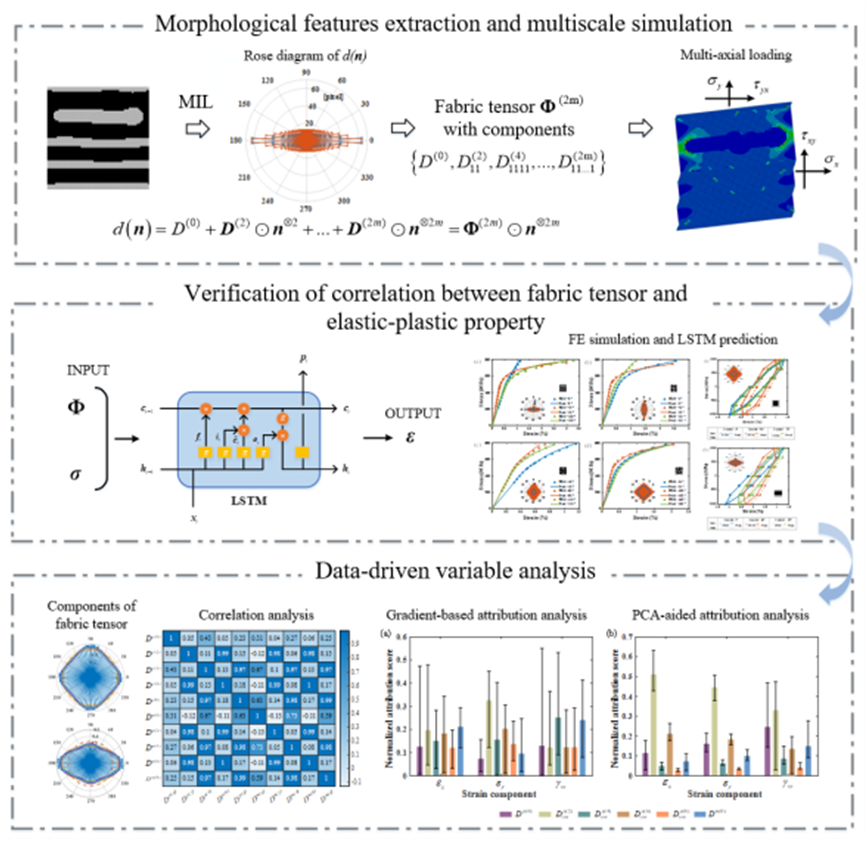

1、 AI empowers intelligent design and multi-scale simulation of composite materials

Background introduction

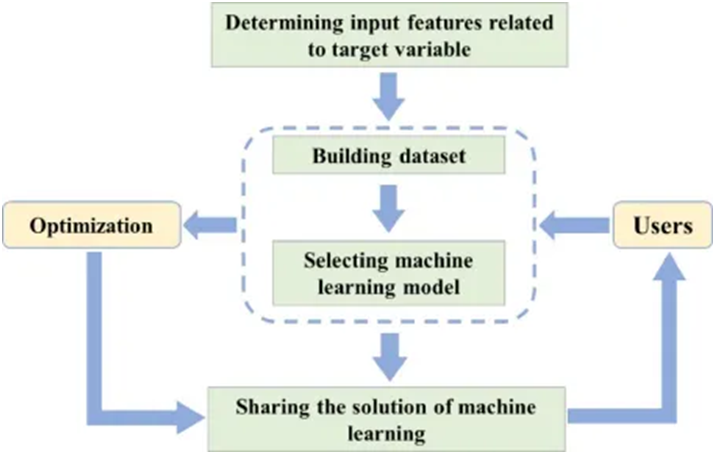

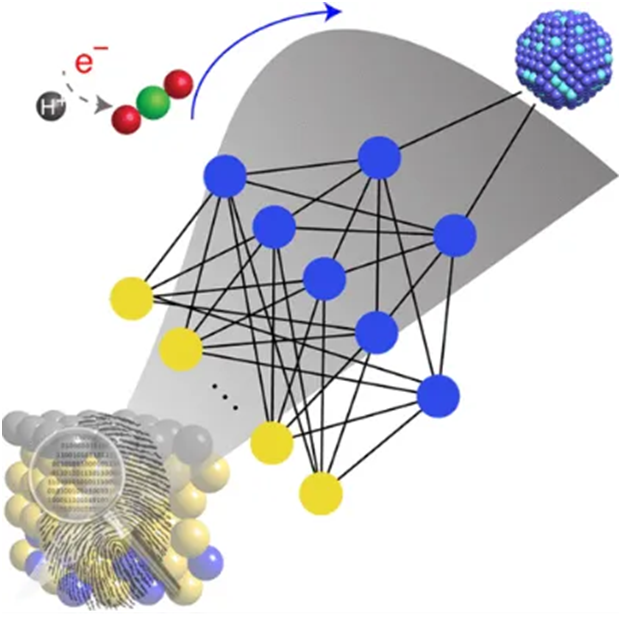

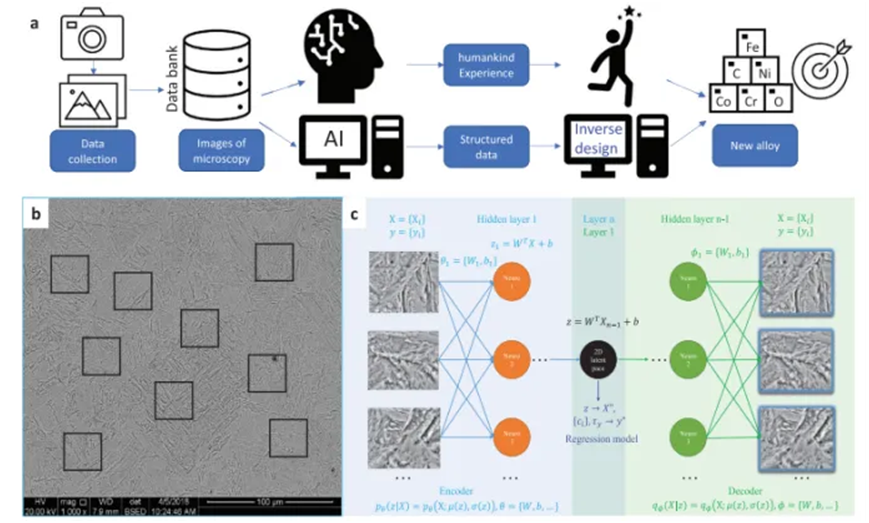

The research background of AI composite materials stems from the severe challenges that traditional composite material development paradigms are facing. The performance of composite materials is determined by countless interdependent variables, such as fiber orientation, layup sequence, process parameters, etc. The "composition structure process performance" relationship is extremely complex, like a difficult to analyze "black box", which leads to traditional methods relying on physical models and trial and error experiments not only being expensive and time-consuming, but also difficult to achieve precise quality control in the manufacturing process, efficient interpretation of non-destructive testing data, and accurate prediction of long-term service performance. At the same time, artificial intelligence (AI) technology, especially machine learning and deep learning, is rapidly developing due to its powerful ability to learn patterns from high-dimensional nonlinear data, efficiency in processing massive amounts of information, and millisecond level real-time prediction advantages. This has prompted researchers to deeply integrate AI into the entire lifecycle of composite material design, manufacturing, testing, and operation, aiming to solve the core pain points mentioned above through a new paradigm of data-driven and intelligent empowerment, achieve reverse design, process optimization, automatic non-destructive evaluation, and accelerate new material discovery, ultimately driving composite material technology towards intelligence, precision, and efficiency to meet the urgent demand for high-performance advanced materials in high-end fields such as aerospace.

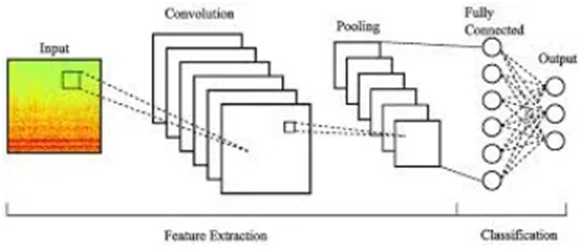

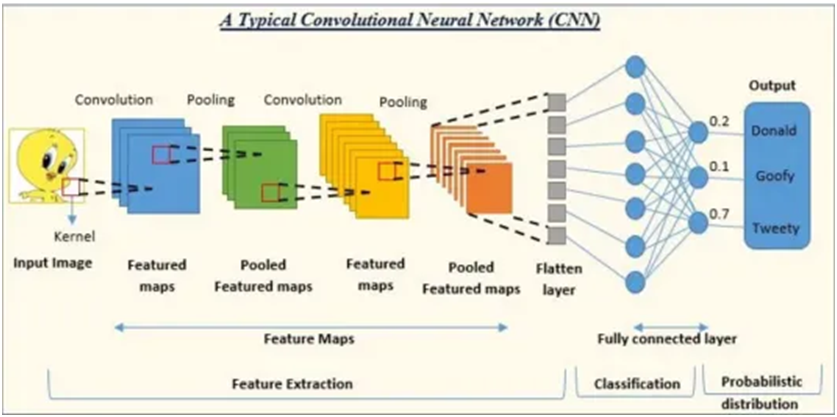

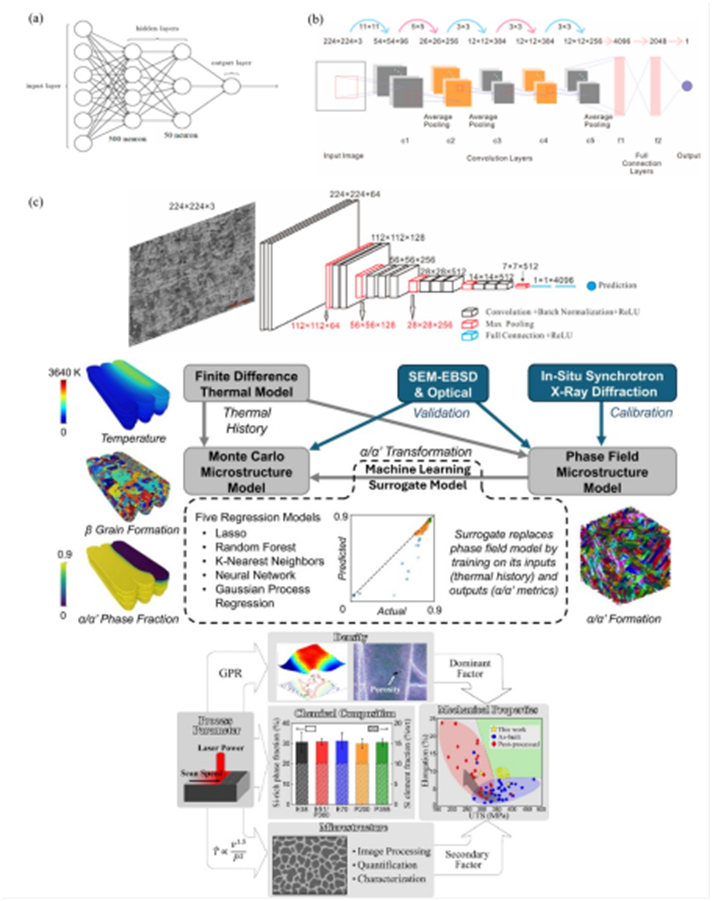

Convolutional Neural Networks and Finite Element Composite Material Damage Prediction

1. Core principles of neural networks and CNN (practical operation+code)

(1) The Evolution Path from Perceptron to Convolutional Neural Network

(2) Convolutional Layer Mathematical Principles: Parameter Sharing and Feature Extraction Mechanism (3) The Mechanism of Pooling Layer and Activation Function

(4) Quick practical operation: manually implementing simple convolution operations

Figure CNN Infrastructure Diagram

(1) From classification to segmentation: FCN network transformation principle

(2) Design concept of encoder decoder architecture

(3) Comparison of Transposed Convolution and Upsampling Strategies

(4) Code demonstration: Building a basic FCN segmentation network

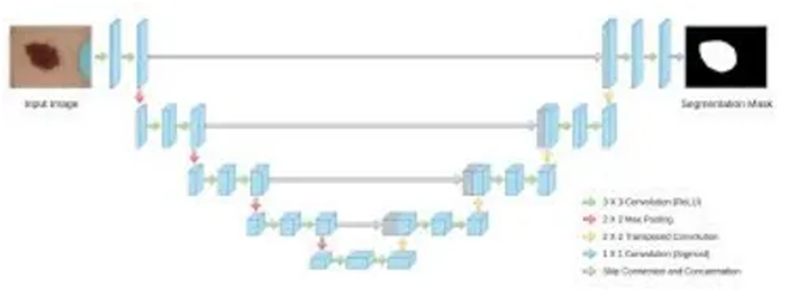

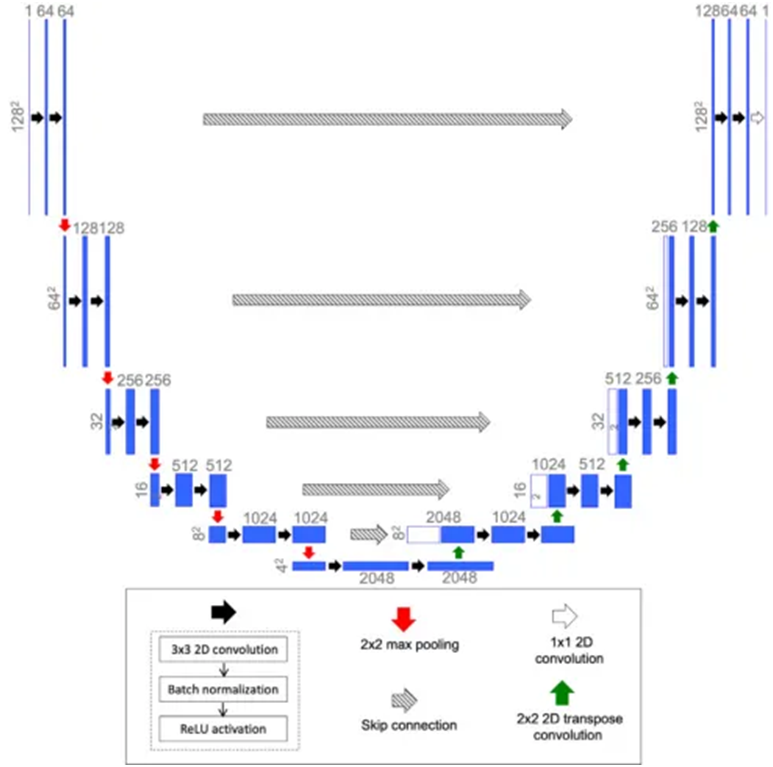

3. Deep analysis of U-Net architecture

(1) Analysis of U-Net Core Architecture (Practical Operation+Code+Demonstration)

(2) Design concept and points of U-Net symmetric structure

(3) The key role of Skip Connection

(4) Scale variation of feature maps and information preservation mechanism

Core practice:

Complete U-Net Network Architecture Construction

Analysis of Changes in Key Level Feature Maps

Figure U-Net complete architecture and information flow diagram

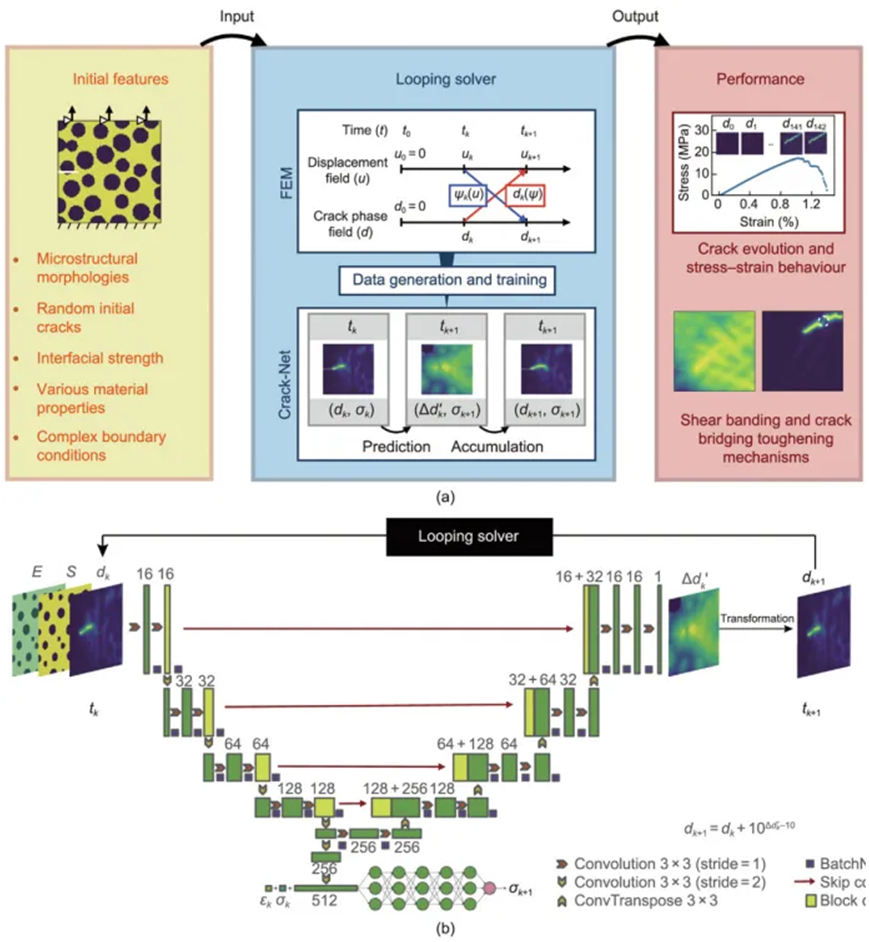

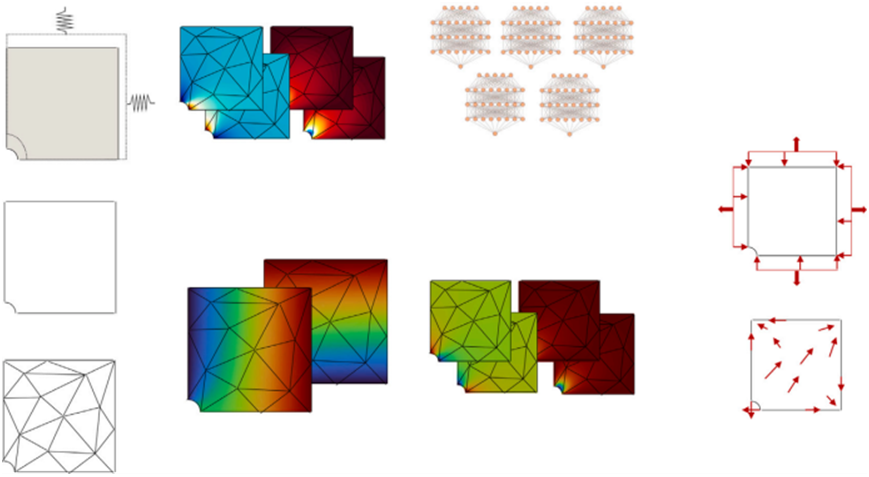

Fundamentals of Finite Element and Phase Field Methods and Core Technologies of Crack Net Architecture

1. Theoretical basis of finite element method phase field damage (practical operation)

(1) The physical meaning and mathematical description of the damage variable d

(2) Phase Field Theory: From Cahn Hilliard to Crack Evolution Practical Implementation: Phase Field Crack Evolution

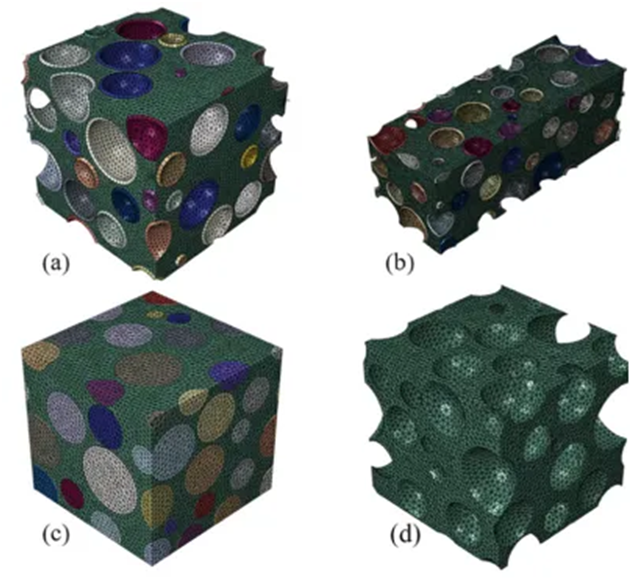

2. Composite material modeling and traditional methods

(1) Simulation of Crack Propagation in Abaqus for Microstructure Modeling of Composite Materials (Practical)

(2) Representative Volume Element (RVE) Design and Periodic Boundary Conditions

(3) Modeling strategy for multiphase material interface

3. Core technology of Crack Net architecture

(1) Evolution from U-Net to Crack Net (practical operation+code+demonstration)

(2) Analysis of the overall architecture design concept of Crack Net

(3) Multi task learning: joint training of stress prediction and phase field prediction

Image: Crack Net Framework

Differential deep learning for stress prediction of composite materials

Background: Starting from the encoder decoder infrastructure, we delve into the cutting-edge application of differential neural networks (DiNN) in stress prediction of composite materials.

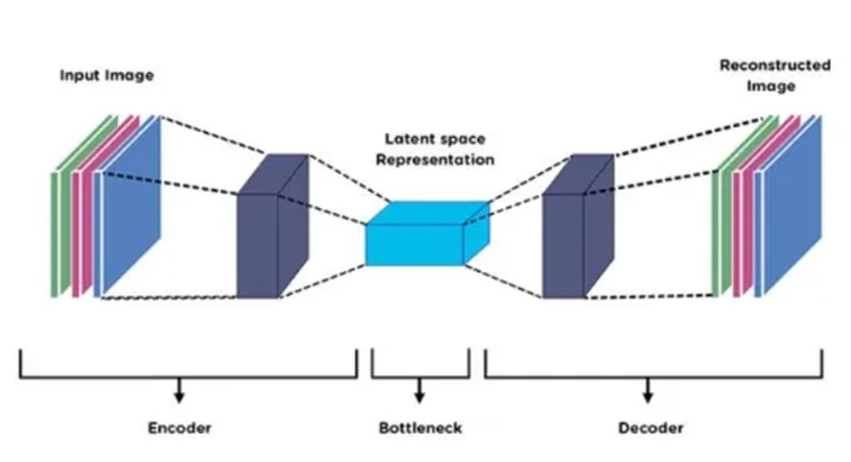

Basic Theory of Encoder Decoder Architecture

1. Core principles of CNN and encoder decoder (practical operation+code) (1) Convolutional neural network feature extraction mechanism and parameter sharing

(2) Design concept of encoder decoder symmetric architecture

(3) Mathematical Principles of Feature Dimensionality Reduction and Reconstruction

(4) Quick Implementation: Building a Basic Encoder Decoder Network

Graph Encoder Decoder Infrastructure Diagram

2. Fundamentals of Image to Image Conversion Network (Practical+Code)

(1) Network adaptation from classification tasks to regression prediction

(2) Spatial information preservation and feature map scale transformation

(3) The mechanism of skip connections in spatial prediction

(4) Code demonstration: Implementing a simple image to image conversion network

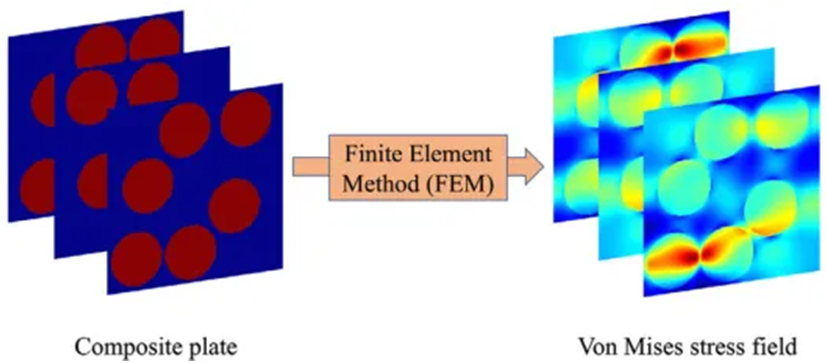

3. Basic theory of finite element stress analysis (practical operation+code)

(1) Basic Equations and Boundary Conditions of Linear Elasticity

(2) Principles of Grid Division and Numerical Solution of Stress Field

(3) Von Mises stress calculation and its physical significance

(4) Quick practical operation: FEA stress calculation for simple structures

4. Center of gravity coordinate interpolation and data standardization (practical operation+code+demonstration) (1) Interpolation challenge from triangular mesh to regular mesh

(2) The Mathematical Principles and Stability Advantages of the Center of Gravity Coordinate System

(3) Cartesian Mapping Data Preprocessing Strategy

(4) Core Practice: Implementation of Center of Gravity Interpolation Algorithm

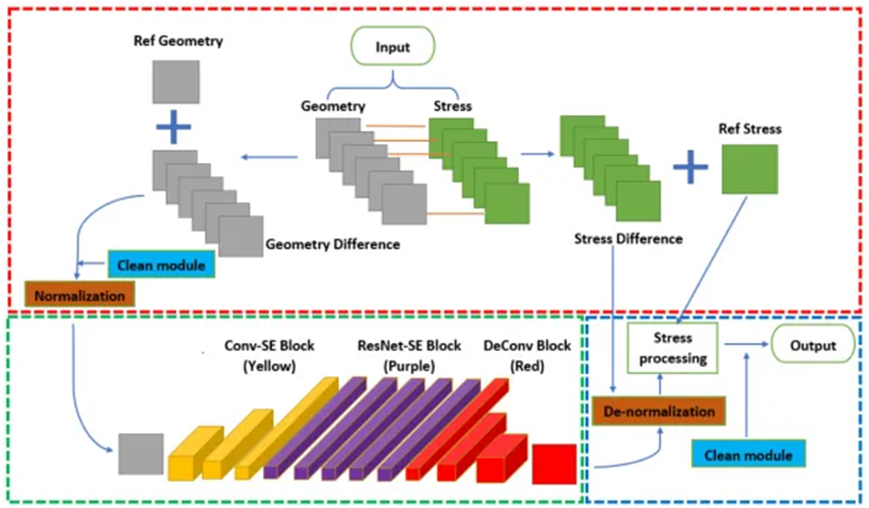

Core Technology of Differential Neural Network (DiNN)

1. From Traditional Methods to Differential Learning Practice (Practice+Code+Demonstration) (1) Limitations Analysis of Traditional End to End Prediction

(2) Differential Learning Philosophy: Reference Models and Differential Training Strategies

(3) DiNN three module architecture: sample processing+encoding and decoding+stress prediction

The complete architecture and point graph of DiNN

2. SE attention mechanism and ResNet fusion technology (practical operation+code) (1) Channel attention mechanism of Squeeze and Excitation block

(2) The collaborative working principle of Conv SE and ResNet SE blocks

(3) Feature recalibration and advanced feature extraction strategy

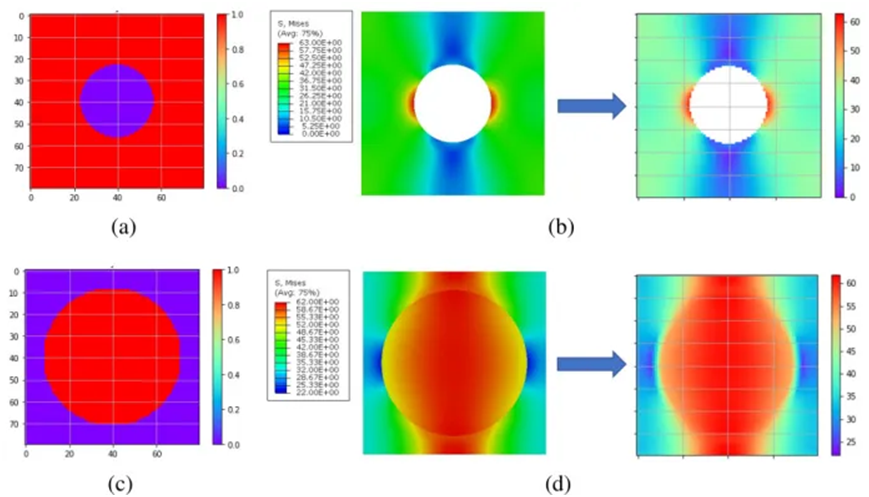

3. Complete process of stress prediction for composite materials (practical operation+code+demonstration) (1) Implementation of stress prediction for typical composite material models

(2) Strategies for handling volume fraction randomness vs. spatial randomness

(3) Accurate prediction technology for stress concentration areas

(4) Engineering case:

Prediction of stress field in fiber-reinforced composite materials

The complete modeling process of particle reinforced composite materials

Comparison of stress prediction results for different composite materials in the figure

Prediction of stress field in composite materials

background

Starting from the foundation of convolutional neural networks, we delve into the application of U-Net architecture in predicting stress fields in fiber-reinforced composite materials.

Deepening the Fundamental Theory of Convolutional Neural Networks

1. Advanced feature extraction mechanism of convolutional neural network (practical operation+code)

1.1 Convolutional Kernel Design Principle: Parameter Efficiency and receptive Field Analysis of 3 × 3 Convolution

1.2 Mathematical balance mechanism between feature map dimensionality reduction and information preservation

1.3 The key role of batch normalization in training stability

1.4 Fast Implementation: Building Multi layer CNN for Complex Pattern Recognition

Figure Multi layer CNN feature extraction mechanism diagram

2.1 Encoder path: Layer by layer feature abstraction and spatial information compression 2.2 Decoder path: Feature reconstruction and spatial resolution recovery mechanism 2.3 Mathematical principle of skip connections: Fusion of high-level semantics and low-level details

Concat operation and information transmission of feature maps at different scales

Detailed practical operation:

Layered construction and parameter analysis of a complete U-Net network

Experimental verification of the impact of skip connections on prediction accuracy

Figure U-Net detailed architecture and skip connection mechanism diagram

Finite element foundation and stress analysis of composite materials

1. Post processing and data extraction methods for stress cloud maps

2. Data preprocessing and image standardization (practical operation+code)

2.1 Generation and Processing of Binary Microstructure Images

2.2 Normalization and Standardization Strategies for Stress Field Data

2.3 Physical rationality analysis of image flipping data enhancement

Depth mapping from microstructure to stress field (practical operation+code+demonstration)

3.1 Encoding strategy for binary fiber distribution image as network input

3.2 Decoding mechanism for continuous stress field as network output

Microstructure Stress Field Mapping Network Architecture Diagram

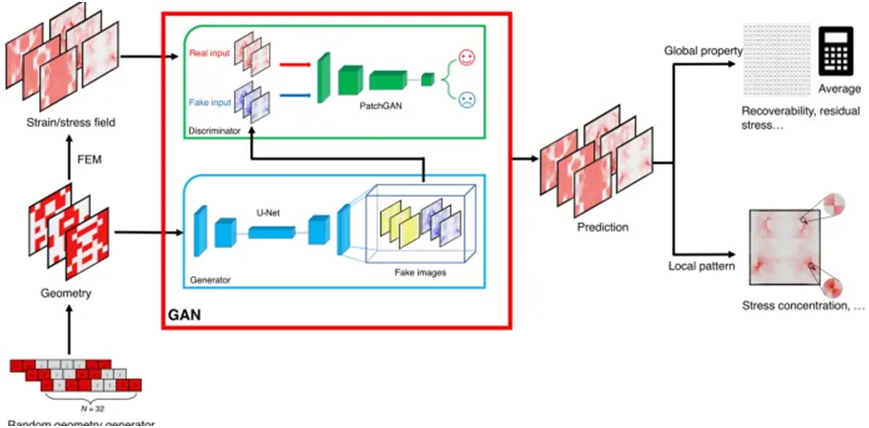

Generate adversarial network for composite material field prediction

Background: Starting from the foundation of generative adversarial networks, we delve into the cutting-edge applications of geometric field mapping in composite material design.

Basic Theory of Generative Adversarial Networks

1. Core principles of Generative Adversarial Networks (GANs) (practical operation+code)

(1) Game Theory Framework: Adversarial Training Mechanism of Generator and Discriminator (2) Mathematical Representation of Nash Equilibrium in Neural Network Training

(3) Constraint mechanism of Conditional Generative Adversarial Network (cGAN)

(4) Quick implementation: Building a basic GAN for image generation

Graph GAN Infrastructure and Game Theory Framework Diagram

Deep analysis of U-Net and PatchGAN architecture (practical operation+code)

Design concept of U-Net encoder decoder symmetric structure

The key role of skip connections in spatial information preservation: PatchGAN local discrimination strategy vs. advantages of global discrimination

Code Demonstration: Application Implementation of U-Net in Image Segmentation

2. Fundamentals of Finite Element Stress Field Calculation (Practice+Code)

(1) Basic equations and constitutive relationships of continuum mechanics

(2) Boundary condition setting and solution strategy under compressive load

(3) The physical significance and calculation method of von Mises stress field

(4) Quick Practice: Stress Field Calculation of Composite Materials in Abaqus

3. Microstructure modeling of composite materials (practical operation+code+demonstration)

(1) Comparison of mechanical parameters of biphasic materials

(2) Residual stress analysis of load unload cycle

Core practice: Analysis of the influence of material parameters on stress field distribution

Microstructure of Composite Materials

Core technology of geometric field mapping

1. Advanced from traditional simulation to intelligent prediction (practical operation+code+demonstration)

(1) Deep Learning Paradigm for Image to Image Conversion

(2) Network design with geometric constraints as conditional inputs

(3) Integrity preservation strategy for physical field information

Geometric GAN framework for composite materials

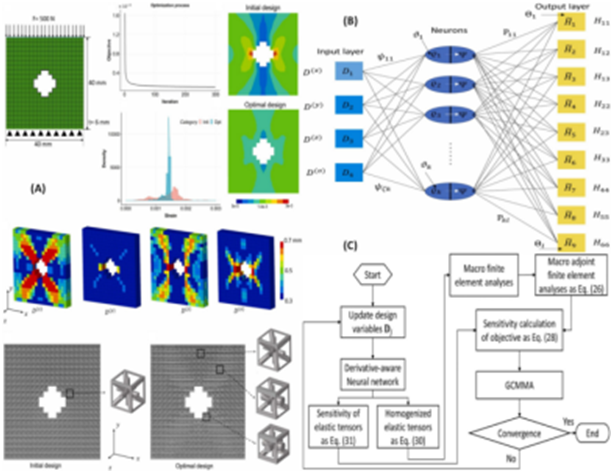

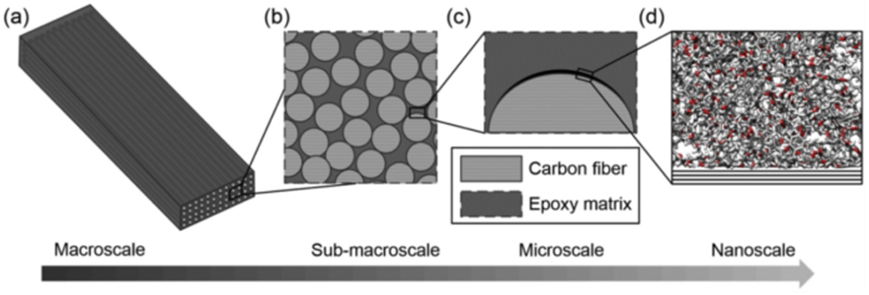

Multi scale composite material performance prediction and intelligent material design

Multi scale performance prediction theory for composite materials

1. Multi scale performance correlation mechanism of composite materials (practical operation+code)

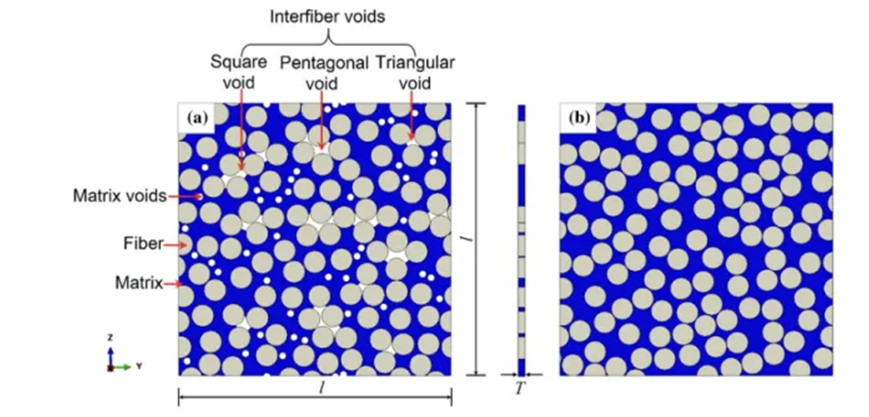

(1) Microstructure characterization of fiber matrix interface three-phase composite materials;

(2) Design principles for composite RVE: fiber volume fraction, distribution pattern, interface properties;

(3) Application of homogenization theory in predicting equivalent properties of composite materials;

(4) Quick Implementation: Parametric Modeling and Performance Prediction of Typical Composite Material RVE

2. Composite material damage mechanism and FE ² coupling analysis (practical operation+code) (1) Typical failure modes of composite materials: fiber fracture, matrix cracking, interface debonding

(2) Multi scale mapping relationship of micro damage evolution under macroscopic loading;

(3) Progressive damage analysis and final failure strength prediction;

(4) Code demonstration: Implementation of FE ² method for damage evolution of composite materials

Multi scale damage evolution mechanism diagram of composite materials

Intelligent Design and Performance Optimization of Composite Materials

3. Development of UMAT intelligent constitutive model for composite materials (practical operation+code+demonstration)

(1) UMAT implementation of anisotropic elastic constitutive model for composite materials;

(2) Integration of Damage Evolution Equation and Neural Network Proxy Model

(3) AI accelerated solution of nonlinear constitutive relationship for composite materials

(4) Core Practice: Writing and Verification of Intelligent UMAT Subroutines for Composite Materials

4. Neural network driven composite material performance prediction system (practical operation+code+demonstration);

(1) End to end prediction of microstructure images to macroscopic properties of composite materials;

(2) Prediction of the influence of fiber orientation and volume fraction on the strength/stiffness of composite materials;

(3) Intelligent evaluation of fatigue life and damage tolerance of composite materials;

(4) Detailed analysis:

Training data generation: collection of performance data for different composite material systems

Multi task learning: simultaneously predicting multiple performance indicators such as elastic modulus, strength, toughness, etc

Diagram of Neural Network Architecture for Predicting Composite Material Properties

2、 Artificial Intelligence Materials Fatigue Analysis and Fracture Mechanics

Machine Learning Fundamentals and Applications of Fatigue Fracture Mechanics

1.1 Overview of Machine Learning

1.1.1 Common Machine Learning Methods

·Artificial Neural Network (ANN)

·Support Vector Regression (SVR)

·Random Forest (RF)

·Gaussian Process Regression (GPR)

1.1.2 Application prospects of engineering materials science

·Typical scenarios for predicting material properties

·Algorithm selection in cross scale modeling

1.2 Core Technologies of Neural Networks

1.2.1 Infrastructure Analysis · Neural Mathematical Model and Activation Function Comparison · Feedforward Network Information Transmission Mechanism

1.2.2 Typical Model Classification

·Limitations of Fully Connected Networks (ANN)

·Convolutional Network (CNN) Spatial Feature Extraction

·Recursive Network (RNN) Temporal Data Processing

1.3 Intelligent Fatigue Fracture Analysis

1.3.1 Key influencing factor system

·Stress amplitude/average stress effect

·Surface state/environmental medium effect

1.3.2 Evolution of Life Prediction Models

·Physics driven model: Paris law extension

·Data driven model: prediction of crack propagation rate

1.4 Practical Fatigue Prediction of 718 Alloy

1.4.1 Data Engineering Construction

·Multi source experimental data fusion method

·Feature Engineering and Standardization Processing

1.4.2 Model Training and Validation

·Parallel Implementation of ANN/SVR/GPR/RF

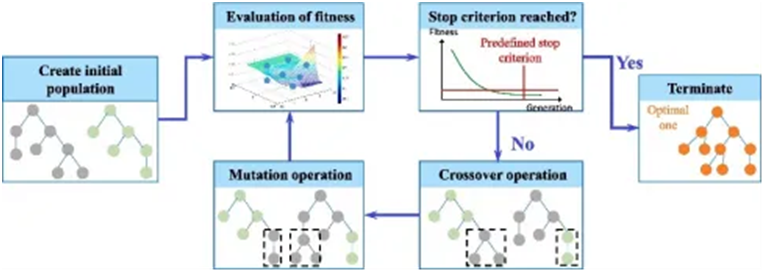

·Cross validation and hyperparameter optimization

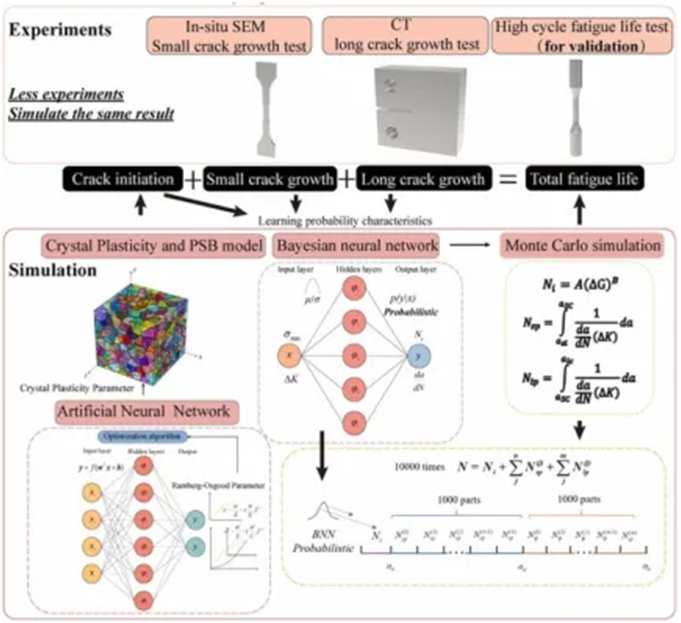

Multi scale analysis and life prediction of fatigue cracks driven by machine learning

2.1 Multi scale analysis techniques for cracks

2.1.1 Cross scale correlation method

·Cross scale modeling of micro dislocation evolution to macro crack propagation

·Machine learning characterization of grain boundary effect and crack deflection

2.1.2 Fundamentals of Damage Mechanics

·Determination of damage threshold for crack initiation and short crack propagation

2.2 Frontier Technologies for Intelligent Life Prediction

2.2.1 Ultrasound Bayes fusion method

·Ultrasonic signal feature extraction and damage index construction

·Real time lifetime update strategy under Bayesian probability framework

2.2.2 Multi scale data-driven framework

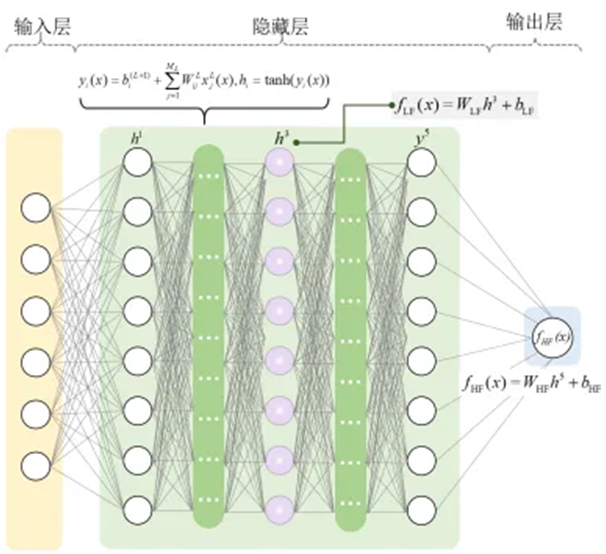

·Crystal plasticity model and ANN model

·Bayesian network architecture for microstructure lifetime correlation

2.3 Practical Application of Low Cycle Fatigue in Austenitic Stainless Steel

2.3.1 Data Engineering System

·Multi source heterogeneous data fusion

·Material feature coding

2.3.2 Hybrid Machine Learning Modeling

·Key feature selection logic of CART decision tree

·XGBoost ANN Integrated Model Architecture

2.3.3 Industrial Validation Scheme

·Visual presentation of feature importance ranking

·Trace the micro mechanism of prediction error

Intelligent analysis of metal fracture surfaces empowered by machine learning

3.1 Theoretical System of Metal Fracture

3.1.1 Basic framework of fracture mechanics

·Theoretical boundary of linear elastic/elastoplastic fracture mechanics

·Application scenarios of stress intensity factors K and J

3.1.2 Crack propagation criteria

·Fatigue crack propagation model based on Paris' law

·R-curve evaluation system based on energy method

3.1.3 Damage Evolution Theory

·Crack initiation threshold in microscopic damage mechanics

·Numerical Implementation Path of Hole Aggregation Model

3.2. Frontiers of Intelligent Analysis Technology

3.2.1 Machine Learning Model Architecture

·Embedding Fracture Criteria in Physical Information Neural Networks (PINN)

·Grain boundary crack prediction using graph neural network (GNN)

3.2.2 Hybrid Modeling Strategy

·Finite Element Deep Learning Coupled Simulation Process

·Transfer learning framework for multi-scale damage evolution

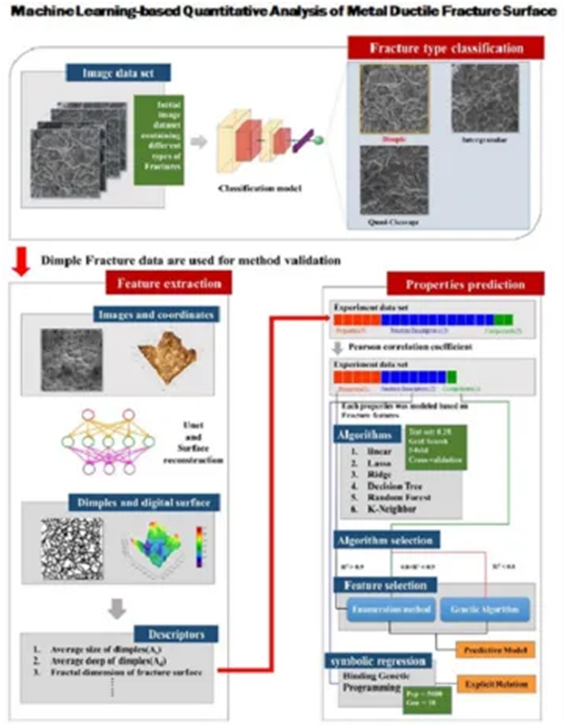

3.3 Practical application of quantitative analysis of fracture surface

3.3.1 Intelligent classification of fracture morphology

·Design of CNN Feature Extraction Network

·Construction of microstructure feature library along crystal/quasi cleavage/toughness pit

3.3.2 Prediction of Mechanical Properties

·Regression prediction model for fracture toughness

·Bayesian optimization method for cross-sectional shrinkage rate

3.3.3 Industrial Validation Scheme

·Visual Error Analysis of Prediction Results

Corrosion fatigue and composite material life prediction

4.1 Corrosion fatigue mechanism and intelligent recognition

4.1.1 Corrosion fatigue coupling mechanism

·Phase field simulation of electrochemical corrosion accelerating crack initiation

·Cross scale characterization of stress corrosion cracking (SCC)

4.1.2 Intelligent detection of welding defects

·Corrosion fatigue crack classification based on ResNet50

·Multimodal fusion of acoustic emission signals and X-ray data

4.2 Composite Material Damage Theory

4.2.1 Microscopic damage evolution

·Competitive mechanism of fiber fracture/matrix cracking/interfacial delamination

·Correlation Model between Damage Thermodynamics and Entropy Production Rate

4.2.2 Multiscale analysis methods

·Construction of Graph Neural Networks for Cross Scale Damage Transmission

4.3 Intelligent prediction system

4.3.1 Physics guided deep learning framework

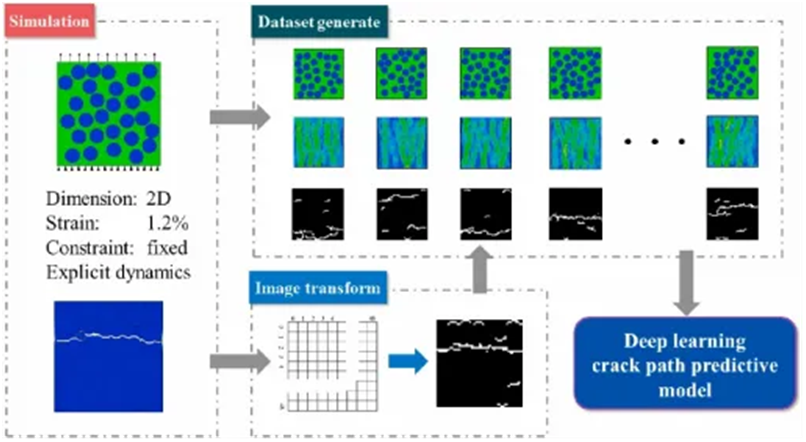

·Machine learning architecture for predicting crack propagation paths

·Design of loss function for constitutive constraints

4.3.2 Semantic segmentation processing of multimodal data engineering μ CT scan data

Intelligent prediction system for metal fatigue in extreme environments

5.1 Extreme working condition damage mechanism

5.1.1 High temperature fatigue creep coupling effect

·Creep damage evolution dominated by dislocation climb

·Cross scale model of oxidation accelerated crack propagation

5.1.2 Physical Information Neural Network Architecture

·Design of loss function for creep fatigue interaction

5.2 Data Enhancement Engineering

5.2.1 Small sample expansion techniques

·Microstructure generation based on Wasserstein GAN

·Interpolation of operating parameters for Gaussian mixture model

5.2.2 Multi scale data fusion

·Optimization of nearest neighbor interpolation for grain boundary slip characteristics

5.3 Frontiers of Multiscale Simulation

5.3.1 Innovation of Damage Analysis Methods

·Phase field crystal plasticity coupling model

5.3.2 Industrial Validation Cases

·Creep fatigue prediction of nickel based alloys

·Transfer learning strategy for error compensation

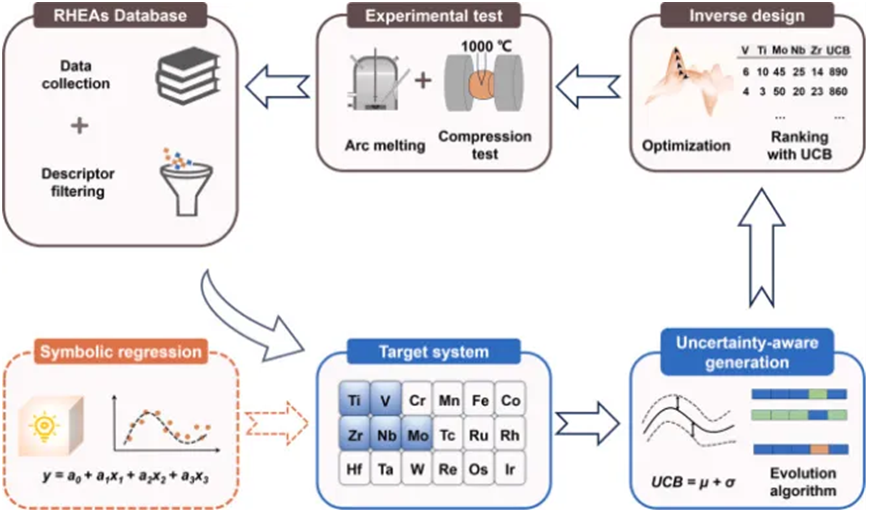

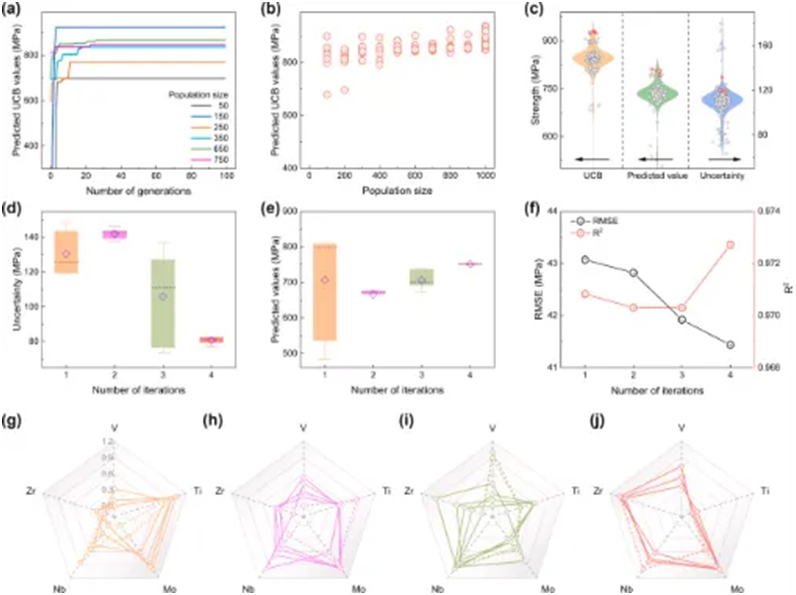

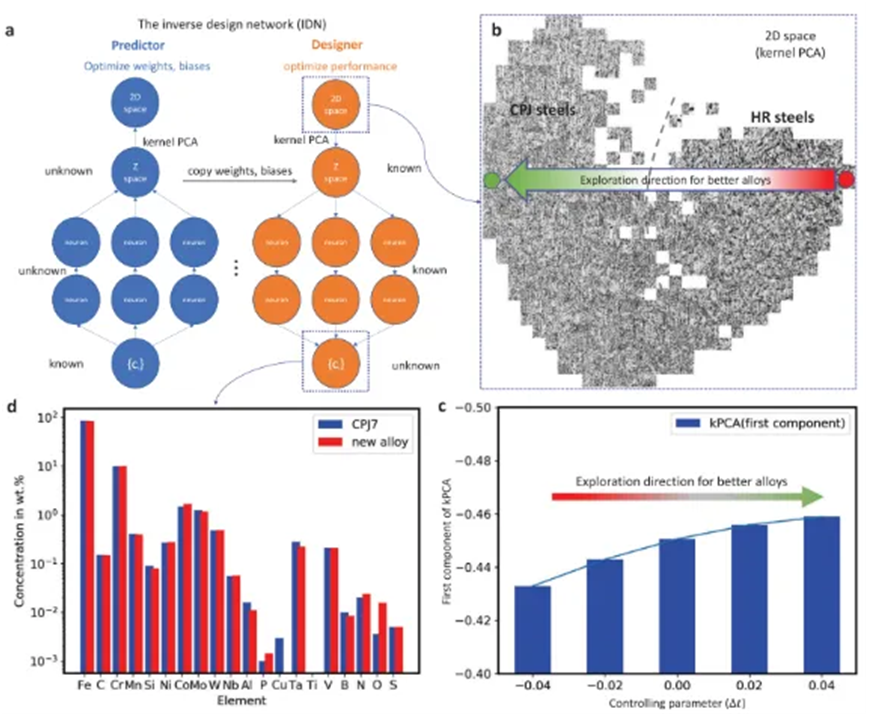

3、 Machine Learning Alloy Design

Application and Development Status of Machine Learning in Alloy Design Field

Introduction to Fundamentals:

Objectives, Pain Points in Alloy Design, and ML Solution Path

History of Domain Development: Paradigm Evolution from Empirical Design → CALPHAD → ML

Core Application Scenarios: Component Optimization/Phase Prediction/Performance Mapping/Reverse Design Cases

2 Data Cornerstones

Data source: Materials Project/ICD/OQMD database practical retrieval

Feature engineering: construction of descriptors such as atomic radius, electronegativity, and valence electron number

Data cleaning: missing value handling/outlier detection/standardization demonstration

3. Algorithm panorama

Supervised Learning: A Typical Model of Regression vs Classification Tasks in Alloys

Unsupervised Learning: Cluster Analysis Discovering Alloy Families (PCA+t-SNE Visualization)

Reinforcement Learning: Conceptual Analysis of Dynamic Component Optimization Framework

4 Challenges and Frontiers

Data bottleneck: small sample learning/transfer learning solutions

Interpretability: SHAP value analysis of dominant factors affecting the performance of high entropy alloys

Trend discussion: Interpretation of the latest papers on generative models/multi-scale modeling

Practical application of composition performance model for alloys based on machine learning

Various alloy element ratios and their service properties (mechanical properties, chemical properties, etc.), using machine learning to predict and explain the relationship between alloy composition and properties.

Using machine learning models to study the relationship between alloy composition and mechanical and chemical properties, predict and explain the service performance under different alloy composition ratios, and the influence of different alloy compositions on service performance.

Using machine learning models to predict the service performance of different alloy compositions

1. Method for establishing a database

2. Use different machine learning models to establish the relationship between alloy composition and service performance, and predict the service performance under different alloy composition ratios (code explanation and operation)

Big Festival | Section | Content Details |

2.1 Modeling Fundamentals | 2.1.1 Problem definition | Composition → Performance Prediction Task Decomposition |

2.1.2 Feature construction | Magpie library automatically generates element features and derives interaction items | |

2.1.2 Feature construction | Multiple linear regression and rapid validation of decision trees | |

2.2 Advanced Model | 2.2.1 Integration method | Random forest optimization key hyperparameters |

2.2.2 Support Vector Machine | Kernel function selection and grid search(RBF vs Poly) | |

2.2.3 Neural network | 3-layer MLP implementation and Dropout anti overfitting | |

2.3 Model Evaluation | 2.3.1 Verification strategy | |

2.3.2 Evaluation metric | MAE/RMSE/R² Interpretation of Continuous Variables | |

2.3.3 Error analysis | Residual graph localization of systematic bias samples | |

2.4 Optimize deployment | 2.4.1 Hyperparameter tuning | Bayesian Optimization library automatic search |

2.4.2 Feature selection | RFECV Recursive feature elimination practical application | |

2.4.3 Lightweight deployment | Lask encapsulation model for API call demonstration |

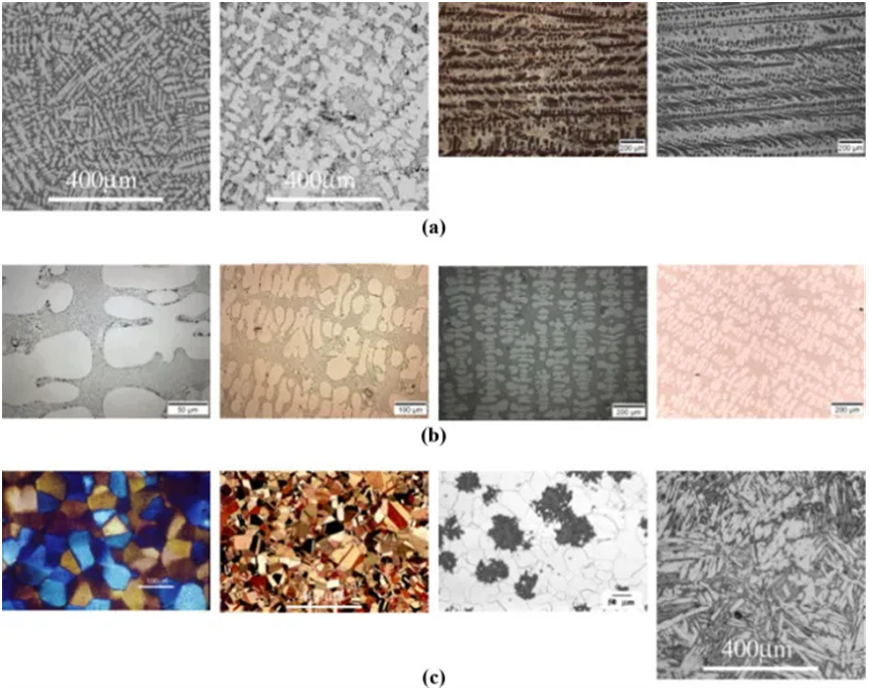

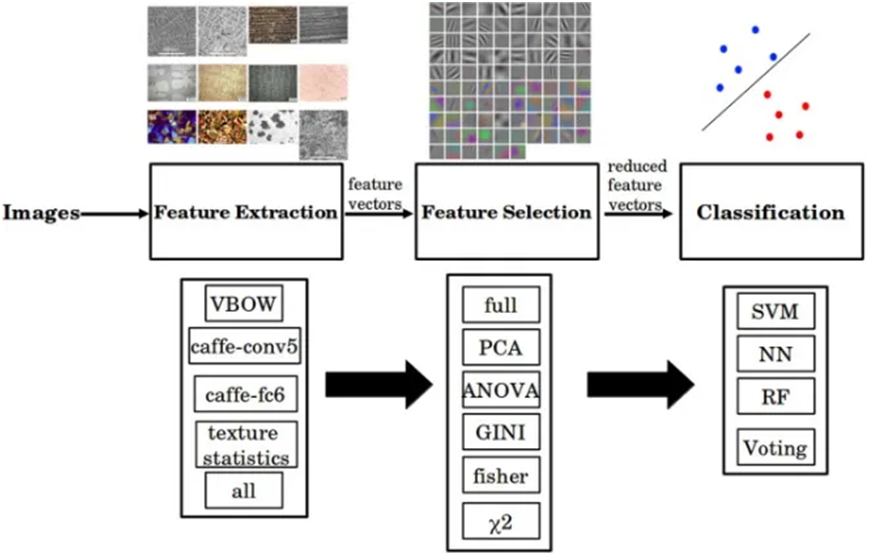

Practical prediction of microstructure mechanical properties of alloys based on machine learning

The structural characteristics of different alloy systems, including microstructure, mesoscopic structure, and macrostructure, are studied using machine learning to investigate the relationship between multi-scale structure and mechanical properties.

Using machine learning to study the relationship between microstructure and mechanical properties of alloys

1. Feature extraction and screening of microstructure images, establishing a database

2. Use different machine learning models to establish the relationship between microstructure and mechanical properties, and predict the service performance under different alloy microstructures (code explanation and operation)

Case: GBDT prediction of high temperature alloy γ&# 39; Actual combat of the influence of phase size on strength

Big Festival | Section | Content Details |

3.1 Data representation | 3.1.1 Image acquisition | SEM/EBSD/TEM Data Format and Preprocessing |

3.1.2 Feature extraction | Statistical methods for grain size/phase ratio/orientation difference | |

3.1.3 Graph Neural Network | Topology characterization of grain boundary network (PyG preliminary) | |

3.2 Traditional method | 3.2.1 Physical model | |

3.2.2 Classic ML | SVM prediction of yield strength | |

3.2.3 Feature fusion | Combined input of components and organizational features improves accuracy | |

3.3 Deep learning | 3.3.1 CNN architecture | U-Net Segmentation of Multiphase Organizations (PyTorch Implementation) |

3.3.2 Transfer Learning | ResNet fine-tuning predicts fatigue life | |

3.3.3 Multi-task learning | Synchronized prediction of strength/elongation |

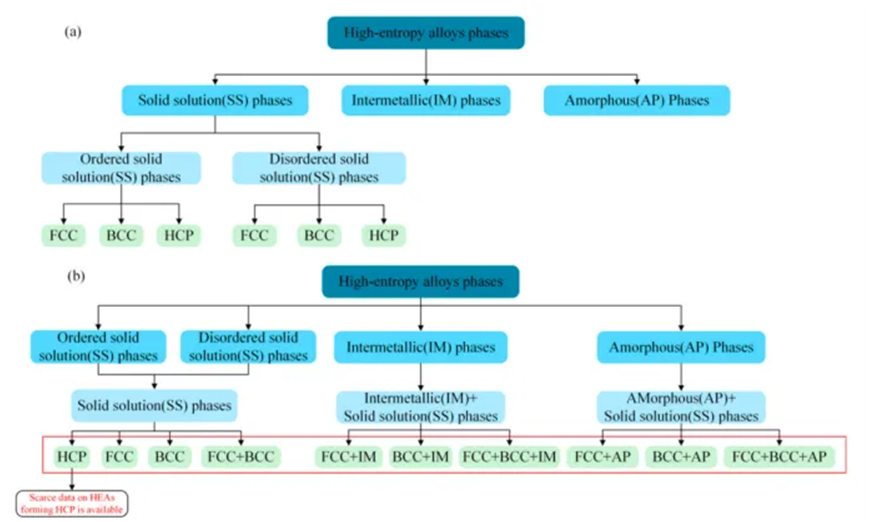

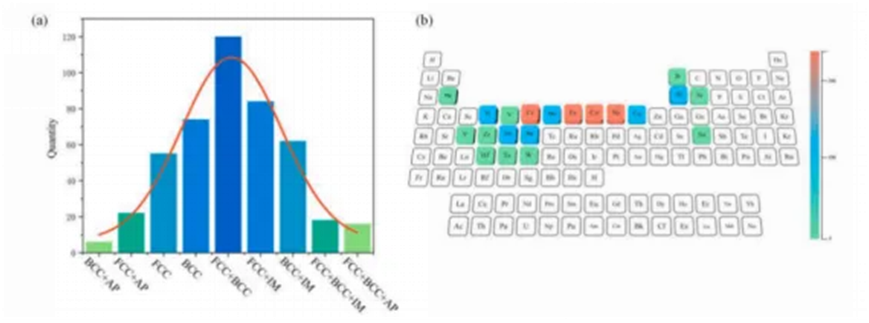

Practical prediction of alloy phase field using composition based on machine learning

The basic principles of common generative AI: VAE, GAN, and their derivative models are introduced. The application of generative AI in alloy design is introduced, such as generating microstructures, classifying and identifying microstructures, etc.

Using GAN to generate microstructure images

Using GAN to learn the relationship between process parameters, alloy composition, and microstructure

1. Code explanation

2. Generate melt pool images using GAN

3. Generate image quality assessment

Case: High entropy alloy microstructure generated based on GAN specified composition

Big Festival | Section | Content Details |

4.1 Phase field foundation | 4.1.1 Principles of Physics | Cahn Hilliard equation and free energy functional |

4.1.2 Numerical simulation | FiPy library phase field simulation demonstration (coarsening of precipitation phase) | |

4.1.3 Computational bottleneck | Introducing ML acceleration requirements to traditional simulation time problems | |

4.2 Alternative model | 4.2.1 Data generation | Constructing phase field dataset through parameterized scanning |

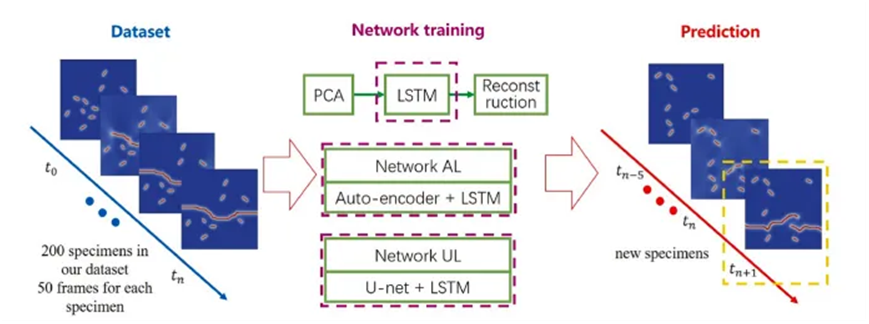

4.2.2 LSTM prediction | Time series prediction of phase evolution path | |

4.3 Frontier methods | 4.3.1 Generative Adversarial Networks | GAN generates microstructural evolution sequences |

4.3.2 Graph Convolutional Network | Predicting grain boundary migration in polycrystalline systems | |

4.3.3 Active learning | Adaptive sampling reduces the number of simulations |

Practical Analysis of Alloy Microstructure Based on Machine Learning

Utilize machine learning to automate or enhance the analysis and understanding process of material microstructure images (such as metallography, scanning electron microscopy, transmission electron microscopy, etc.).

Project practice utilizes machine learning models to identify microstructures

Case: CNN based phase segmentation of high-temperature alloys

Big Festival | Section | Content Details |

5.1 Image analysis | 5.1.1 Advanced segmentation | Mask R-CNN instance segmentation precipitation phase |

5.1.2 3D reconstruction | Reconstruction of 3D tissue using layer scan sequence (Tomopy library) | |

5.2 Generate Design | 5.2.1 VAE Fundamentals | Variational autoencoder compresses organizational feature space |

5.2.2 CGAN application | Conditional generation of target microstructure (specified grain size) | |

5.3 Reverse optimization | 5.3.1 Bayesian optimization | Search for optimal process parameters to achieve target organization |

5.3.2 Reinforcement Learning |

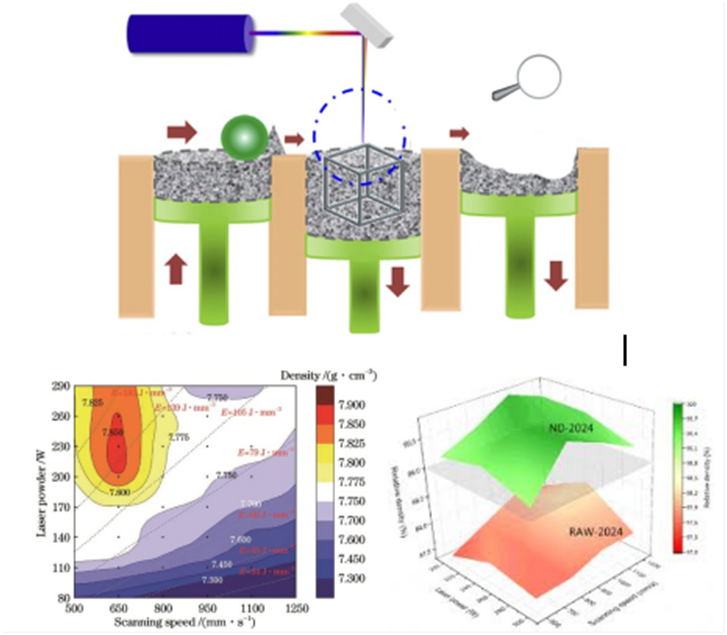

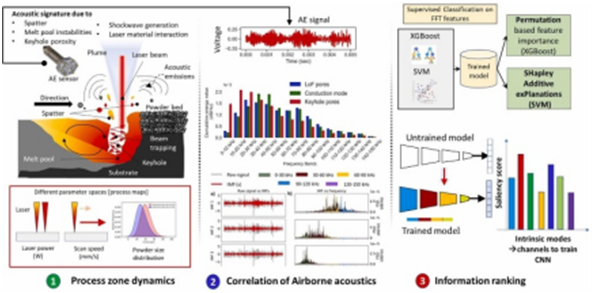

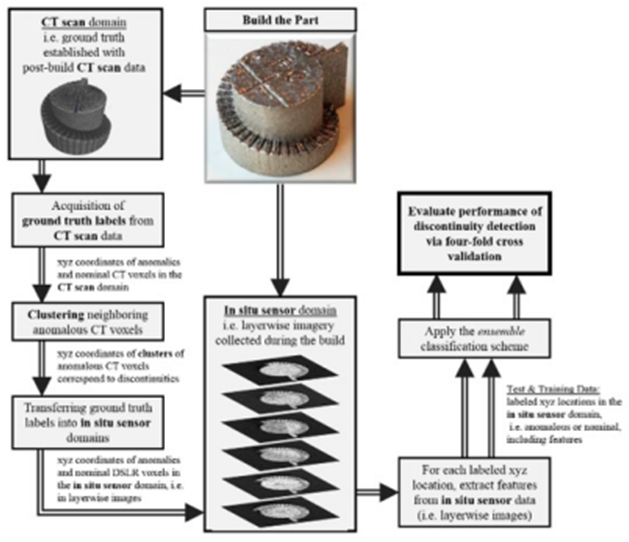

IV. Practical application of machine learning in additive manufacturing

AI model and additive manufacturing application foundation

1.1 Additive manufacturing process system and key challenges

·Powder bed fusion technology: laser/electron beam-powder interaction mechanism of SLS (non-metal) and SLM/EBM (metal)

·Directional energy deposition technology: molten pool dynamics characteristics of LENS process

Fused Deposition Modeling (FDM) technology: Extrusion-remelting behavior of FDM metal wire material

1.1.1 Stability challenges in additive manufacturing process

· Bath instability (splashing, spheroidization)

·Deformation and cracking caused by interlayer thermal stress

·Powder spreading uniformity and inert gas flow field disturbance

1.1.2 Defect control dimension

·Porosity and morphological characteristics of incomplete fusion defects

·The influence of microstructural anisotropy on mechanical properties

·Post-processing (hot isostatic pressing, heat treatment) mechanism for defect repair 1.2 Adaptability of AI model architecture to additive manufacturing

1.2.1 Basic Framework of Machine Learning · Supervised Learning (Process Parameter-Quality Indicator Mapping)

·Unsupervised learning (defect pattern clustering analysis)

·Reinforcement learning (dynamic process parameter adjustment)

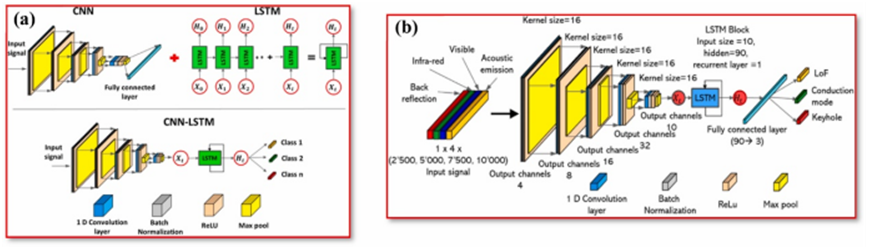

1.2.2 Deep learning specific model

·CNN is used for feature extraction of molten pool images

·LSTM processes time-series thermal history data

·GAN generates synthetic training data to compensate for experimental shortcomings

1.3 Intelligent analysis of the relationship between process parameters and defects

1.3.1 Comparative experiment of multi-algorithm density prediction

Input parameters: laser power, scanning speed, layer thickness, preheating temperature

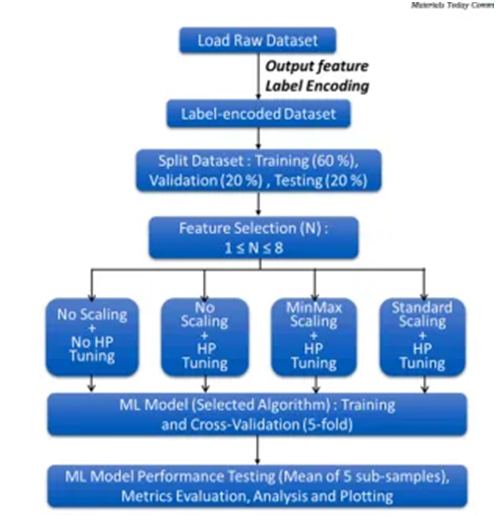

Algorithm Pool: Support Vector Regression (SVR), Decision Tree (DT), Random Forest (RF), Gaussian Process Regression (GPR), K-Nearest Neighbors (KNN), Stochastic Gradient Descent, Multi-Layer Perceptron, XGBOOST, and Artificial Neural Network (ANN) are supported to study the relationship between process parameters and relative density in selective laser melting technology manufacturing. The goal is to improve the density of parts by optimizing process parameters.

Validation metrics: R² score, MAE, cross-validation stability

1.3.2 Cross-process Transfer Learning Framework

·Under small sample conditions, a domain adaptation algorithm based on Transfer Learning (TL) enhances model generalization ability to address the challenge of device variability

Optimization of SLM process for Ti-6Al-4V alloy driven by machine learning

Objective: To predict the impact of laser power (P), scanning speed (v), and hatch spacing (h) on relative density (ρ) using classical machine learning algorithms

1.4.1 Environment configuration and data engineering

1.4.2 Toolchain deployment

·Python 3.8+ environment setup (Anaconda recommended) ·PyCharm project structure:

·Key library installation:

1.4.3 Data preprocessing process

Data acquisition: Import the SLM process dataset (including approximately 300 sets of Ti-6Al-4V experimental data) published by the author from GitHub

Outlier handling:

Feature engineering:

1.4.4 Core steps of machine learning modeling

1.4.5 Design of algorithm comparison experiment

1.4.6 Result visualization and process optimization

1.4.7 Evaluation index system

1.4.8 Discussion of limitations · Impact of material batch differences · Multi-objective optimization requirements (density vs residual stress)

Explainable machine learning-driven decoding of structure-property relationship for additive manufacturing alloys

2.1 Multi-scale structural feature library of additive manufacturing alloys

2.1.1 Microstructural fingerprint

·EBSD quantification method for grain size (aspect ratio/orientation)

· CT scanning and 3D reconstruction of porosity/lack of fusion defects

2.1.2 Mesoscopic structural network

·Analysis of grain boundary network connectivity

·Phase distribution topological parameters (α/β phase ratio, lamellar spacing)

2.1.3 Macrostructural Features

·Orientation and mechanical anisotropy of sedimentary layer zones

·Correlation between surface roughness and mechanical properties

2.2 Explainable Machine Learning Framework

2.2.1 Algorithm selection and physical adaptation

2.2.2 Interpretability evaluation and verification

2.3 Physical field coupling strategy

· Thermo-mechanical coupled field data as input features (temperature gradient/cooling rate)

·The results of crystal plasticity finite element analysis serve as prior knowledge to constrain the loss function

2.4 Case Study: Intelligent Correlation Analysis of Microstructure-Mechanical Properties

Objective: To establish a quantitative relationship between the thickness of α-phase lamellae and the tensile strength of Ti-6Al-4V through machine learning

2.4.1 Microstructural feature engineering

2.4.2 Construction of high-precision image database · Data sources:

2.4.3 Feature selection strategy · Physically driven selection: Retain grain size-related features based on the Hall-Petch formula · Data-driven selection: Rank features by importance using XGBoost

2.4.4 Core of Machine Learning Modeling

2.4.5 Multi-algorithm comparative experiment

2.4.6 Key code logic

2.4.7 Interpretability analysis

Machine learning in additive manufacturing process monitoring and application

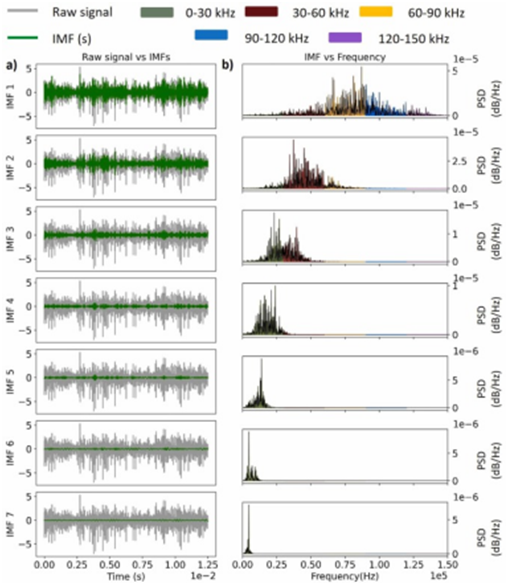

3.1 Sensing signal feature library for additive manufacturing process

3.1.1 Physical characteristics of signal modality

• Acoustic emission signal: characteristic frequency band of cracks/lack of fusion (100-300kHz)

• Molten pool optical signal: correlation between plasma radiation intensity and porosity • Infrared thermal imaging: mapping of interlayer temperature gradient and residual stress 3.1.2 Multi-sensor data fusion framework

• Time-frequency domain feature extraction (wavelet transform/short-time Fourier transform)

• Cross-modal feature alignment method (dynamic time warping algorithm)

3.2 Heterogeneous data classification algorithm

• For high-frequency acoustic signals: 1D-CNN temporal feature extraction architecture • For multispectral optical signals: Attention mechanism enhanced ResNet network

3.3 Case Study: Defect Traceability in Laser Powder Bed Fusion Process Objective: Establish a classification model from acoustic-optical signal characteristics to defect types (porosity/spheroidization/cracks)

3.3.1 Data preprocessing

• Acoustic signal processing:

• Optical signal processing:

3.3.2 Model interpretability analysis

• SHAP value analysis

• Physical mechanism verification

3.3.3 System integration demonstration

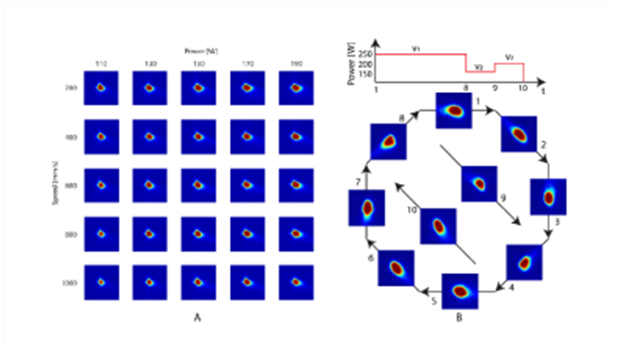

Digital twin of additive manufacturing process driven by generative AI

4.1 Analysis of generative AI model architecture

4.1.1 Comparison of core models

• VAE: Advantages of Continuity in Latent Space and Interpolation of Process Parameters

• GAN: High-fidelity generation capability of molten pool morphology (WGAN-GP addresses mode collapse)

• Derivative model

CycleGAN is used for cross-process parameter domain transfer (laser power → scanning speed mapping)

·StyleGAN2 achieves multi-scale microstructure generation (α/β phase stratification control)

4.2 Specialized Model Design for Additive Manufacturing

• Design of loss function under physical constraints:

·Generation of molten pool aspect ratio constrained by heat conduction equation

·Statistical matching of crystal orientation with EBSD measured data

·Multimodal input architecture

·Process parameters (power/speed/layer thickness) serve as input conditions for Conditional GAN;

4.3 Digital Twin of Bath Dynamics

• End-to-end prediction of weld pool geometry based on process parameters using pix2pixHD

• Time-series generation model (LSTM-GAN) predicts interlayer thermal accumulation effect

4.4 Microstructure inverse design

• Exploration of VAE latent space: Reverse derivation of optimal lattice structure from mechanical properties6

• Adversarial generative network achieves adversarial repair of stomatal defects

4.5 Case Study: Ti-6Al-4V Laser Melt Pool Generation System Objective: Construct a WGAN-GP generation model for process parameters (P, v) → melt pool morphology

4.5.1 Data Engineering

• Simulation data construction

4.5.2 Model development core

• Key code module

• Training strategy

4.5.3 Generate a quality assessment system

• Quantitative indicators:

- FID score: Feature Distance assessment of generated and simulated molten pools 4

- Geometric conformity: calculation of Hausdorff distance of molten pool contour

• Physical verification:

- Comparison of the thermal history curve of the molten pool generated and the CFD simulation results

Real-time quality monitoring system for additive manufacturing driven by multimodal sensing

5.1 Innovation in hybrid model architecture

5.1.1 Spatio-temporal feature fusion architecture

• CNN-LSTM-Attention three-stage processing flow:

oCNN branch: Processing X-ray Computed Tomography (XCT) images (spatial feature extraction)

oLSTM branch: Analyzing the temporal characteristics of acoustic emission signals (crack propagation dynamics modeling)

oAttention mechanism: dynamic weighted multi-sensor feature importance

• Physical constraint design:

Thermo-acoustic coupling loss function (matching between molten pool oscillation frequency and acoustic emission spectrum)

5.2 Industrial-grade defect classification system

5.2.1 Multi-scale defect detection framework:

Macro defects (porosity/lack of fusion): XCT + optical signal fusion classification

Microdefects (microcracks/precipitated phases): collaborative analysis of EBSD and acoustic emission signals

• Real-time optimization:

Model quantization (with FP16 precision) achieves a single-frame processing delay of<50ms

5.2.2 Cross-modal data fusion technology

• Time stamp synchronization: Phase locking of X-ray pulse and acoustic emission signal

• Spatial registration: 3D affine transformation of optical images and XCT volumetric data

5.3 Feature engineering innovation

5.3.1 Acoustic emission signal processing:

o Improve MFCC feature extraction (by increasing the weight of the molten pool oscillation frequency band) o Conduct envelope analysis to detect microcrack initiation events

5.3.2 Data pipeline construction

• Multi-source data collection:

- Synchronous trigger protocol design (synchronization of X-ray pulse and acoustic emission acquisition clock)

- Data augmentation: defect simulation under process parameter perturbation (random fluctuation of ±15% in power)

• Feature normalization:

- XCT grayscale value normalization (Hounsfield unit conversion)

- Acoustic emission signal wavelet denoising (Symlets basis function optimization) 5.3 Core model implementation and training techniques

5.4.1 Hybrid model architecture:

5.4.2 Training optimization

- Gradual training strategy: Initially train the single-modality branch independently, followed by joint fine-tuning

- Adversarial example augmentation: FGSM attack simulates sensor noise

5.4 Industrial verification system

• Quantitative indicators:

- F1-score of defect classification: XCT modality (0.92) vs multi-modality fusion (0.97)

- Real-time testing: average delay of 43ms (meeting the production line takt time requirements)

• Physical verification:

- The spatial error between XCT tomographic scanning and metallographic sectioning is less than 25μm

- The positioning accuracy of acoustic emission events reaches ±2mm

5. Artificial Intelligence Finite Element Simulation

Deep Learning Algorithm Theory and Practice

1-Python installation and environment configuration method

Creation and common methods of 2-tensor

3-Implementing basic optimization concepts and the least squares method in Python

4 - Introduction to Deep Learning with Pytorch

5-Single-layer neural network

6 - Deep neural network

7 - Loss function of neural network

8 - Neural network construction based on PyTorch

Practical application of composite materials based on multi-scale simulation and artificial neural networks

1. Background and concept of multi-scale technology

1.1 Development of multiscale technology

1.2 Types of multiscale techniques

1.3 Implementation methods of multi-scale technology

2. Secondary development of ABAQUS and Python

2.1 Overview of ABAQUS scripts

2.2 Basic framework for secondary development of ABAQUS

2.3 Python script interface

2.4 CAE environment development and user subroutine development

2.5 Introduction to Python Language

2.6 ABAQUS scripting

2.7 Secondary development of RVE model with aggregate/fiber

3. Multi-scale FE2 method driven by artificial neural network

3.1 Detailed explanation of collaborative multi-scale FE2 method technology

3.2 Overview of the ABAQUS collaborative multiscale method based on UMAT

3.3 Implementation of collaborative multiscale simulation in ABAQUS based on UMAT

3.4 Introduction to ANN network architecture

3.5 Specific framework of advanced FE2 method driven by high-fidelity FE2 based on ANN

4. Practical application of deep learning-based prediction of mechanical properties of metallic materials and modeling of structure-property relationships

4.1. Convolutional Neural Networks and Material Property Prediction

4.2 Basic Principles of CNN and Systematic Introduction to Material Science Applications: Core Concepts and Fundamental Theories of Convolutional Neural Networks;

4.3 CNN Feature Extraction of Microstructure Images: A Detailed Explanation on How to Design a CNN Model Suitable for the Microstructural Characteristics of Materials

4.4 Introduction to the CNN-based mechanical property prediction system for multiphase materials, focusing on the CNN-based mechanical property prediction method

5. Optimization and Implementation of Deep Neural Network Models;

5.1 Detailed introduction to the design of multi-channel Siamese network structure and its application in materials science

5.2 In-depth discussion on loss function design and training strategy: Design of loss functions suitable for material property prediction

5.3 Implementation of multiphase metal material strength prediction based on TensorFlow Through a complete TensorFlow code example,

5.4 CPFE-DNN Integrated Prediction of Additive Manufacturing Stainless Steel Properties: A Detailed Introduction to the Application of CPFE-DNN Integrated Method in Predicting the Properties of Additive Manufacturing Stainless Steel

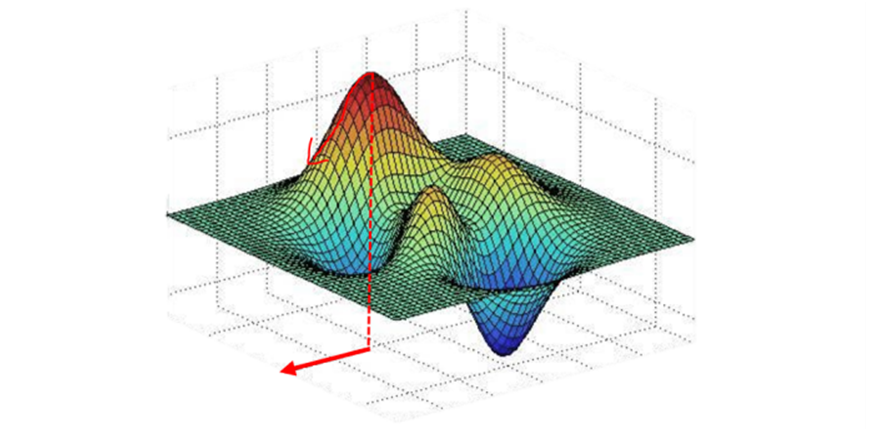

Practical application of deep learning-based hyperelastic materials using stress-free data

1. Analysis of mechanical behavior of hyperelastic materials

1.1 Hyperelastic material mechanical behavior

1.2 Hyperelastic material simulation analysis (case)

2. Input Convex Neural Network (ICNN)

2.1 Introduction to ICNN technology

2.2 Specific implementation and explanation of ICNN technology (case study)

3. Unsupervised deep learning hyperelastic constitutive law

3.1 Problem setting

3.2 Approximate displacement field from point-wise data

3.3 Constitutive model based on neural network

3.4 Constitutive model of unsupervised learning

4. Numerical benchmark

4.1 Data generation

4.2 Data model accuracy, generalization, and FEM deployment

Real-world application of material constitutive reconstruction based on physically constrained artificial neural network architecture

1. Theories related to physical constraints

1.1 Deformation mapping

1.2 Deformation gradient

1.3 Cauchy-Green deformation tensor

2. Overview of physical information in neural networks

2.1 Physical rationality constraints

3. Application and Implementation of Physical Constraints in Neural Network Models

3.1 Construction of a Purely Data-Driven Neural Network Model (Case Study)

3.2 Construction of energy-driven neural network model (case)

3.3 Construction of neural network model based on PDE (case study)

4. Integration of neural network architecture based on physical information and simulation technology

4.1 UANISOHYPER_INV Artificial Neural Network Constitutive Subroutine

4.2 Integration of artificial neural networks based on physical information and simulation technology

4.3 Fusion strategy of neural network model and traditional numerical simulation method

5. Design and Implementation of a Metal Defect Detection System Based on Convolutional Neural Networks for Practical Applications

5.1 Analysis of classic CNN models

5.2 Design and optimization of deep CNN

5.3 Defect detection method based on classification

5.4 Segmentation-based defect localization technology

5.5 Application of Ensemble Methods such as Bagging, Boosting, and Stacking in Defect Detection

Practical application of multi-scale damage modeling for two-phase high-temperature alloys based on recurrent neural networks

1. Multi-scale modeling based on homogenization

1.1 Formation strategy of two-phase alloy in phase field

1.2 Homogenization calculation method in Abaqus

2. Finite element modeling of coupled damage in crystal plasticity

2.1 Basic theory and framework of crystal plasticity finite element method, implementation strategy of finite element UMAT, implicit stress integration using tangent coefficient method, and slip system damage modeling.

3. Temporal multiscale simulation and dataset construction

3.1 Batch multi-scale finite element simulation techniques

3.2 Establish a constitutive behavior dataset recognizable by neural networks

3.3 Compare the advantages and disadvantages of network methods such as FCNN, RNN, and LSTM in modeling cyclic plastic behavior.

4. Modeling of intelligent crystal plasticity

4.1 Fusion mechanism and method of physical information in this construction model

4.2 Network architecture design for crystal plastic slip deformation.

5. Tensorial description of microstructures and its intelligent importance evaluation

5.1 Tensorial description method for microstructure of two-phase materials

5.2, Identify key microstructural parameters through artificial intelligence.

6. Research on model performance under multi-axis loading

6.1 Prediction research on the mechanical behavior of two-phase microstructures with different morphologies under multi-axis loading,

6.2 Alloy damage mechanism under multi-axis loading