How to choose thermal conductive silicone grease? Hard core analysis of seven core parameters

1、Thermal conductivity

Among the many parameters of thermal conductive silicone grease, thermal conductivity is undoubtedly the most critical and can be regarded as the "core engine" of heat dissipation performance. Its unit is W/(m · K). This parameter intuitively reflects the ability of silicone grease to conduct heat, and the higher the value, the faster the heat can be transferred through the silicone grease.

For computers used in ordinary households, generally, choosing thermal conductive silicone grease with a thermal conductivity of 4W/(m · K) or higher can meet the basic daily heat dissipation needs. For example, office software such as Word and Excel that run during daily office work, as well as occasional online video watching, web browsing, and other operations, generate relatively less heat from computer hardware. This type of thermal conductivity silicone grease is sufficient to smoothly transfer the heat generated by the CPU to the heat sink, thereby maintaining the stable operation of the CPU within a suitable temperature range and ensuring the smooth completion of various daily tasks on the computer.

But when it comes to high-performance gaming consoles or professional graphics workstations, the situation is quite different. The core hardware of these devices, such as CPUs and GPUs, releases a large amount of heat when running large games, performing complex graphics rendering or scientific computing tasks with high workloads. At this point, higher thermal conductivity silicone grease is needed to ensure heat dissipation efficiency. It is generally recommended to choose products with a thermal conductivity of 6W/(m · K) or higher, such as some high-end thermal conductive silicone grease, whose thermal conductivity can even reach 10W/(m · K) or higher. High thermal conductivity enables heat to quickly pass through the silicone grease layer, quickly transfer to the heat sink, and dissipate to the surrounding environment in a timely manner, effectively preventing hardware performance degradation due to overheating, ensuring that the device can maintain strong performance under high load operation, allowing gamers to enjoy a smooth gaming experience, and professionals to efficiently complete complex work tasks.

However, it should be noted that although thermal conductivity is an important indicator for measuring the performance of thermal conductive silicone grease, the quality of silicone grease cannot be judged solely based on this parameter. In the actual selection process, it is necessary to comprehensively evaluate other parameters such as thermal resistance in order to select the most suitable thermal grease for one's own equipment.

2、Thermal resistance

Thermal resistance is another key factor in measuring the performance of thermal conductive silicone grease. It is like a "resistance scale" on the heat conduction path, reflecting the degree of obstruction of silicone grease to heat conduction, measured in ℃/W. In principle, the lower the value of thermal resistance, the smaller the temperature difference generated at both ends of the thermal conduction path under the same heat conduction power, which undoubtedly indicates better heat dissipation effect

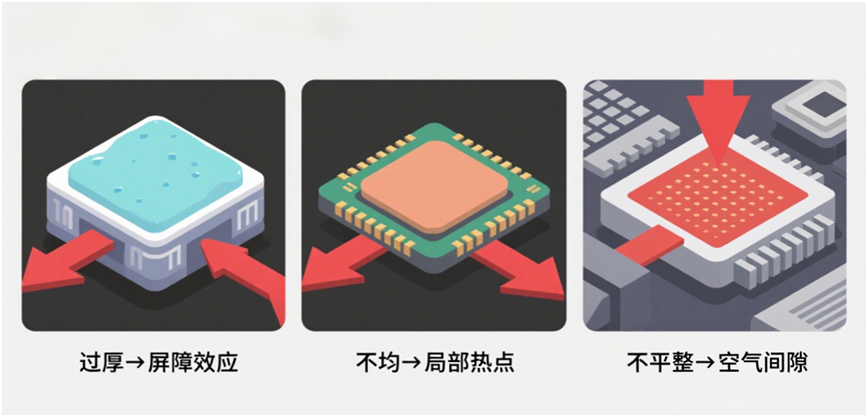

Although thermal resistance and thermal conductivity are closely related, they have significant differences. Generally speaking, the higher the thermal conductivity of thermal grease, the lower its thermal resistance, because better thermal conductivity means less resistance to heat transfer. However, thermal resistance does not solely depend on thermal conductivity. In practical applications, it is influenced by various factors, and is more affected by the thickness of silicone grease, uniformity of application, and flatness of the contact surface than thermal conductivity. Excessive application of silicone grease is like setting up a thick barrier on the path of heat transfer, which significantly increases thermal resistance and makes it difficult for heat to transfer smoothly; Uneven application can cause local thermal resistance to be too high or too low, affecting the overall heat dissipation balance; However, if the contact surface is uneven, even if the thermal conductivity of silicone grease is high, the presence of a large number of small gaps will hinder heat transfer due to the low thermal conductivity of air, thereby increasing thermal resistance.

Taking laptops as an example, due to their compact internal space and limited heat dissipation, the thermal resistance requirements for thermal conductive silicone grease are more stringent. When choosing thermal conductive silicone grease, it is necessary to carefully compare the thermal resistance data of similar products and prioritize selecting models that have shown excellent thermal resistance performance in actual testing. In this way, when the laptop is running under high load, such as long-term video editing or running large games, the low thermal resistance thermal conductive silicone grease can quickly transfer the heat generated by core hardware such as CPU and GPU, accurately control the working temperature of the hardware, avoid frequency reduction caused by high temperature, and improve the stability of the entire system, allowing users to smoothly complete various tasks and enjoy a stable and efficient user experience.

3、Oil viscosity

Oil separation degree, as an important indicator for measuring the quality of thermal conductive silicone grease, reflects the amount of silicone oil precipitation under high temperature conditions, and can be regarded as a long-term and stable "quality touchstone". In actual use, silicone grease will be affected by the heat generated by equipment operation, especially under long-term high load operation, the temperature will continue to rise. If the oil separation degree is high, a large amount of silicone oil in the silicone grease will precipitate.

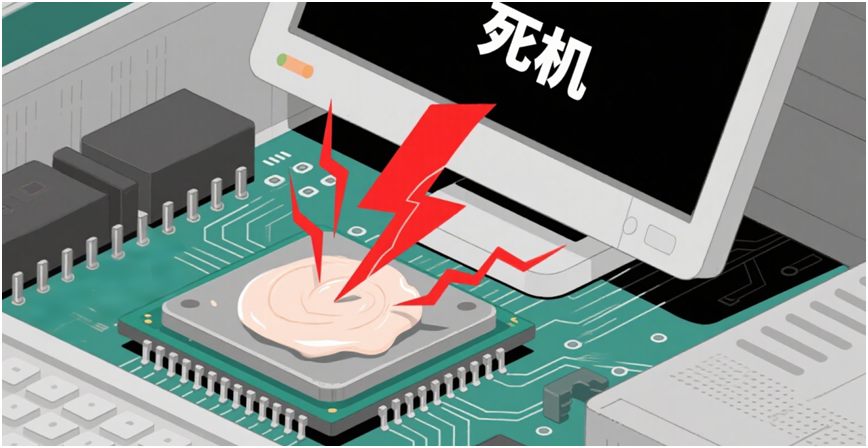

Imagine when you are streaming a 3D game for a long time, your computer's CPU and GPU are running at full capacity, generating a lot of heat. At this point, if the thermal conductivity of the silicone grease used is too high, the silicone oil will continuously precipitate, and the silicone grease will gradually dry out. The silicone grease layer that was originally tightly filled between the hardware and the heat sink will crack, causing damage to the heat dissipation channel and ineffective heat transfer. Moreover, the precipitated silicone oil may also seep onto other electronic components, not only affecting aesthetics, but more seriously, it may cause corrosion to electronic components, affecting their normal operation and even leading to hardware damage.

On the contrary, high-quality thermal conductive silicone grease has lower oil separation, and can maintain a good paste like shape even after long-term use in high temperature environments. It can continuously and stably fill the tiny gaps between the hardware and the heat sink, ensuring smooth heat conduction and maintaining the stable operating temperature of the hardware. Just like some high-end servers that require uninterrupted operation 24/7, they have extremely high requirements for the oil separation of thermal grease. Only high-quality silicone grease with low oil separation can meet the heat dissipation needs of servers for long-term stable operation, ensuring the efficiency and stability of data processing.

There are some simple methods to determine the degree of oil separation when selecting thermal conductive silicone grease. You can apply a small amount of silicone grease on white paper and observe it after a period of time. If there are obvious oil stains spreading on the paper, it indicates that the oil separation degree of the silicone grease is high; You can also refer to the product manual. Regular products usually indicate the specific value or range of oil separation. The lower the value, the lower the oil separation, and the more reliable the product quality.

4、Working temperature range

The working temperature range is a key parameter that must be carefully considered in the practical application of thermal conductive silicone grease. It determines whether the silicone grease can maintain stable performance in different high and low temperature environments, and can be called an "environmental adapter" that adapts to all scenarios. Generally speaking, high-quality thermal conductive silicone grease products can maintain relatively stable performance within a wide temperature range of -50 ℃ to 230 ℃.

When choosing thermal grease, it is crucial to closely integrate it with the actual working environment of the equipment. Taking laptops as an example, their usage scenarios are diverse and sometimes they may be used in cold outdoor environments, where the ambient temperature may approach or even fall below 0 ℃; When playing games or complex graphics processing indoors for a long time, the computer hardware runs under high load for a long time, and the internal temperature will rise sharply. The temperature near core components such as CPU and GPU may reach 80 ℃ or even higher. This requires the selected thermal conductive silicone grease to be able to adapt to this large temperature range, without becoming too viscous at low temperatures and affecting thermal conductivity efficiency, and without significant performance degradation due to excessive volatilization of silicone oil or changes in other components at high temperatures. It should always maintain good heat transfer performance to ensure stable operation of laptops in various usage scenarios.

For industrial control equipment, its working environment may be more extreme. In some special industrial production environments, equipment may face high temperature environments near high-temperature furnaces, with temperatures far exceeding 100 ℃; Or in some low-temperature refrigeration equipment, it is necessary to withstand temperatures close to or even lower than -20 ℃. In these extreme high and low temperature environments, ordinary thermal grease may not be able to handle it, and it is necessary to choose products with a wider working temperature range and more stable performance. Only in this way can we ensure that industrial control equipment, regardless of the harsh temperature environment, will not experience a sharp change in viscosity or significant performance degradation due to temperature fluctuations throughout its entire life cycle. We will always maintain reliable thermal conductivity, ensure the normal operation of industrial production, and avoid production accidents and economic losses caused by equipment overheating or poor heat dissipation.

5、Electrical insulation

In electronic devices, electrical insulation is a crucial performance indicator for thermal conductive silicone grease. It is like a silent "invisible protective shield" that constantly ensures the safe and stable operation of the circuit.

When electronic devices are powered on, their internal electronic components work together in complex circuits, generating a large amount of heat. Thermal conductive silicone grease, as a key medium connecting heating elements and heat sinks, must have good electrical insulation performance while transferring heat. Once the electrical insulation is insufficient, it may lead to serious consequences. Imagine when a computer is running a large 3A game, the CPU and GPU are working at full capacity, generating a large amount of heat. If the insulation performance of the thermal grease used is poor, it may form a conductive path in a high-temperature environment, causing a short circuit fault. This not only causes the computer to crash instantly, losing ongoing game progress, but may also cause permanent hardware damage, resulting in high repair costs.

Ordinary thermal conductive silicone grease usually uses materials with good insulation properties, such as alumina, zinc oxide, boron nitride, etc., as fillers in formula design. These materials can effectively block the conduction of current while improving thermal conductivity, ensuring that there will be no unexpected conductivity between electronic components and heat sinks, thereby ensuring the electrical safety of equipment. However, there are also some special thermal conductive silicone grease on the market, such as silver containing silicone grease. Due to the addition of conductive metal fillers such as silver powder, although its thermal conductivity may be better, it also has a certain degree of conductivity. When using this type of thermal grease, extra caution is required.

During the process of applying thermal grease, it is important to ensure that the grease only covers the area where the heating element and heat sink need to come into contact, and must not come into contact with the pins or other circuit parts of electronic components. Once the conductive silicone grease accidentally comes into contact with the pins, it is like burying a "time bomb" in the circuit, which may cause a short circuit and equipment failure at any time.

In order to ensure that the selected thermal grease meets the safety requirements of the equipment, special attention can be paid to the dielectric constant or volume resistivity parameters of the product when purchasing. The dielectric constant is used to measure the performance of insulators in storing electrical energy. The larger the value, the stronger the ability to bind charges, and the better the insulation performance; The volume resistivity reflects the degree of obstruction of the material to the current, and the higher the resistivity, the better the insulation performance. Especially in high-frequency and high-speed circuit scenarios, the signal transmission speed is extremely fast, and the stability requirements for the circuit are extremely high. At this time, it is even more necessary to choose thermal conductive silicone grease with excellent electrical insulation performance to prevent signal interference and circuit failures caused by insufficient electrical insulation, ensuring that the equipment can still operate stably and efficiently in complex working environments.

6、Brand and reputation

In the selection process of thermal conductive silicone grease, brand and reputation are like "experience endorsements" for quality assurance, playing an indispensable and important role.

Famous brands usually have deep technical expertise and mature production processes in the field of thermal conductive silicone grease. Taking Xinyue as an example, as a globally renowned chemical enterprise, Xinyue has nearly a hundred years of history in the research and production of organic silicon materials. Its thermal conductive silicone grease products, such as the classic X-23-7921 series, have become the preferred heat dissipation material for many high-end servers, laptops, and professional gaming equipment due to their excellent thermal conductivity and stability, and are highly recognized by professionals in the industry. Long term market cultivation has enabled it to accumulate rich production experience, strictly control product quality, and ensure that each batch of thermal conductive silicone grease has stable and reliable performance.

Noctua is also one of the highly acclaimed brands, known for its rigorous research and development attitude and ultimate pursuit of quality. The NT-H1 thermal paste launched by this brand not only performs well in thermal conductivity, but also has excellent durability and compatibility. Whether paired with its own radiator or used in combination with other brands of cooling devices, Owl can demonstrate excellent cooling effects, which has earned the trust of many users worldwide and established a high brand reputation.

As a well-known domestic heat dissipation brand, Cooler Master has extremely high cost-effectiveness in its products. For many years, Coolcool Supreme has focused on the research and innovation of heat dissipation technology, launching a series of thermal conductive silicone grease products suitable for different user needs. These products are made of high-quality materials with good thermal conductivity and stability, which can meet the daily heat dissipation needs of most users. By continuously optimizing product performance and improving user experience, CoolCool Supreme has accumulated a good reputation in the market and become one of the popular brands for consumers when choosing thermal silicone grease.

When selecting thermal conductive silicone grease, referring to professional evaluations and user feedback is an important way to understand the actual performance of the product. Professional evaluation agencies usually use scientifically rigorous testing methods to conduct comprehensive performance tests on different brands and models of thermal conductive silicone grease, including the determination of key parameters such as thermal conductivity, thermal resistance, and oil separation, as well as the evaluation of actual heat dissipation effects in different usage scenarios. These evaluation results can provide consumers with objective and accurate product information, helping them understand the performance differences between different products and make more informed choices.

User feedback can reflect the advantages and disadvantages of the product from the perspective of actual use. For example, on some computer hardware forums and social media platforms, users will share their real experience of using thermal conductive silicone grease, including the difficulty of applying silicone grease, the improvement of heat dissipation effect after use, the stability performance after long-term use, and the satisfaction of after-sales support. By reviewing these user feedback, we can understand potential issues that may arise during actual use of the product, as well as feedback and suggestions from other users, in order to better assess whether the product is suitable for our needs.

Choosing well-known brands of thermal grease and referring to professional evaluations and user feedback can greatly reduce the risk of purchasing inferior products. Poor quality thermal conductive silicone grease may not only fail to provide good heat dissipation, resulting in high temperatures during equipment operation, affecting performance and stability, but may also cause hardware damage due to quality issues, resulting in unnecessary economic losses. Therefore, when choosing thermal grease, we must not only focus on affordability but also consider the importance of brand and reputation. We must consider multiple factors and choose a product with reliable quality and excellent performance to provide strong guarantees for the stable operation of the equipment.

7、Construction difficulty

The difficulty of construction is a crucial factor that cannot be ignored in the practical application of thermal conductive silicone grease. It directly affects the user's experience during operation and the final heat dissipation effect, and can be regarded as a "practical bonus" for efficient operation.

The difficulty of construction is mainly reflected in the viscosity and ease of application of silicone grease. Generally speaking, thermal conductive silicone grease with a viscosity ranging from 40000 to 250000 millipascals per second has good spreading and adhesion properties. This type of silicone grease can be easily and evenly spread around the surface of the chip under a certain pressure when applied, while ensuring a certain degree of viscosity and preventing excess silicone grease from flowing freely after compression. When we apply this type of silicone grease to computer CPUs, we only need to use appropriate tools such as scrapers or built-in applicators to evenly apply the silicone grease to the surface of the CPU, filling the small gaps between the CPU and the heat sink, laying the foundation for efficient heat transfer.

However, if the silicone grease is too thin, it will bring a series of problems. During the application process, it may flow uncontrollably. Once it reaches other electronic components on the motherboard, it not only pollutes the motherboard and affects its appearance, but more seriously, it may cause faults such as short circuits, causing irreversible damage to computer hardware. On the contrary, if the silicone grease is too thick, it will be very difficult to apply and require a lot of time and effort to spread it evenly. Moreover, too thick silicone grease is difficult to completely cover the surface of the heating element, which can lead to uneven application, resulting in excessive local thermal resistance and ineffective heat transfer, thereby affecting the overall heat dissipation effect.

For DIY users, when choosing thermal silicone grease, in addition to focusing on its performance parameters, priority should also be given to products that come with application tools or use needle tube packaging. Products that come with application tools, such as some thermal grease kits, will be equipped with specialized scrapers or applicators. These tools are well-designed, easy to use, and can help users apply grease more accurately and evenly. The thermal conductive silicone grease packaged in a needle tube, like the glue stick we use in daily life, can easily control the extrusion amount of silicone grease by squeezing the needle tube, avoiding the waste and pollution problems that may occur during the traditional canned silicone grease retrieval process. This packaging form is particularly suitable for users who require high construction accuracy and low usage, allowing them to apply silicone grease more easily, ensuring that the silicone grease layer is thin and uniform, and fully exerting its thermal conductivity.

It is also crucial to master the correct method when applying thermal grease. Firstly, it is necessary to ensure that the surfaces of the heating element and radiator are clean and free of impurities such as dust and oil, otherwise it will affect the adhesion effect of the silicone grease. You can use high-purity anhydrous alcohol and a clean lint free cloth to wipe until the surface is as shiny as new. Then, based on the characteristics and packaging form of silicone grease, choose the appropriate application method. For needle type silicone grease, an appropriate amount of silicone grease can be extruded from the center of the heating element, and then evenly pushed away by a scraper or the pressure of the radiator itself; For silicone grease that comes with an application tool, it can be applied according to the tool's instructions. Regardless of the method used, attention should be paid to the thickness of the coating. Generally speaking, the thinner the silicone grease layer, the better. As long as it can fill the gap between the heating element and the heat sink, it is sufficient. An excessively thick silicone grease layer will actually increase thermal resistance and reduce heat dissipation efficiency.

The difficulty of construction is one of the important factors that need to be comprehensively considered when choosing thermal conductive silicone grease. The appropriate viscosity and convenient application method can make it easier and more efficient for users to install or replace thermal grease, ensuring that the grease can fully exert its thermal conductivity and provide stable and reliable heat dissipation for electronic devices. While pursuing high-performance thermal conductive silicone grease, we should not overlook the practical bonus of construction difficulty. Only by balancing both can we keep our electronic devices in the best working condition at all times.