Encyclopedia: What is superhard abrasive

Superhard abrasives mainly refer to diamond and cubic boron nitride (CBN). Diamond is currently the hardest substance known in the world, and CBN's hardness is second only to diamond. These two types of superhard abrasives have much higher hardness than other materials, including grinding tool materials such as corundum and silicon carbide, as well as tool materials such as hard alloys and high-speed steel. When used as grinding wheel abrasives in the field of mechanical processing, they have the advantages of slow wear, high grinding ratio, low grinding force, and low heat generation. They play an irreplaceable role in advanced processing technologies such as high-speed and ultra high speed processing, precision and ultra precision processing, high-precision surface processing, intelligent and unmanned processing, etc.

Diamond

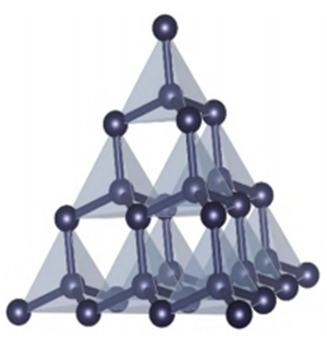

Diamond is composed of carbon elements, and each carbon atom forms covalent bonds with the surrounding four carbon atoms in sp3 hybridized orbitals, forming a three-dimensional network. This network belongs to a face centered cubic lattice structure, with a lattice constant of a=3.5667 Å at room temperature and atmospheric pressure. It has the highest atomic density (176nm-3) and the highest atomic bonding energy (7.4eV), and the perfect lattice structure and bonding method endow diamond with various ultimate properties.

Diamond crystal structure

Diamond is generally divided into natural diamond and synthetic diamond. The preparation methods of synthetic diamond mainly include high temperature and high pressure method and chemical vapor deposition method. According to the differences in crystal structure, diamond can be divided into single crystal diamond and polycrystalline diamond. Diamond is currently one of the materials with the highest known hardness, with a Mohs hardness of 10 and a microhardness of over 10000 kgf/mm ². At the same time, diamond has excellent wear resistance and good thermal conductivity, which gives diamond abrasives significant advantages in grinding high hardness materials. It is widely used in various fields such as hard alloy processing, optical processing, semiconductor polishing, and high hardness drill bits and cutting tools. However, as diamond is an allotrope of carbon, it is prone to chemical reactions with iron-based elements in steel at high temperatures, causing chemical wear and directly affecting the grinding performance and wear of abrasives and grinding tools. Therefore, it is not suitable for processing such materials.

PDS diamond abrasive, source: Haiborui Material Technology official website

Cubic boron nitride(CBN)

Cubic boron nitride is a crystal with a cubic structure composed of nitrogen and boron atoms. It is transformed from hexagonal boron nitride (hBN) under high pressure and high temperature conditions. It is a high-strength and highly wear-resistant superhard abrasive with excellent hardness close to diamond and excellent thermal stability. It is considered one of the greatest technological advances in abrasive history. Compared with traditional abrasives such as alumina and silicon carbide, CBN abrasive has high hardness, wear resistance, and thermal conductivity. Its wear resistance and hardness are more than four times that of traditional abrasives, and its unique chemical properties make it particularly suitable for grinding black metal materials.

Cubic Boron Nitride, Source: Boron Nitride Technology

Diamond and cubic boron nitride materials have been widely used in the fields of grinding and polishing. Superhard material grinding tools refer to tools made of diamond or cubic boron nitride as abrasives, with the help of binders or other auxiliary materials, under certain production conditions, with certain shapes and properties, and used for grinding, grinding, polishing and other processing purposes. It is one of the earliest superhard material products in China. Its product types mainly include fixed grinding tools, coated grinding tools, and paste like liquid grinding tools. According to the different structures and shapes, superhard material grinding tools are divided into grinding wheels, grinding heads, cutting pieces, grinding discs, oilstones, sanding belts, polishing films, grinding pastes, grinding liquids, etc.

Diamond grinding wheel (upper row) and CBN grinding wheel (lower row), source: Wuhan Shengzhongda Diamond Technology Co., Ltd